What is the difference between CO2 laser and fiber laser

They�ll help you reduce gas costs, improve efficiencies, step up your cycle times,and increase overall profit�thanks to superior design and the best resonators on the market.

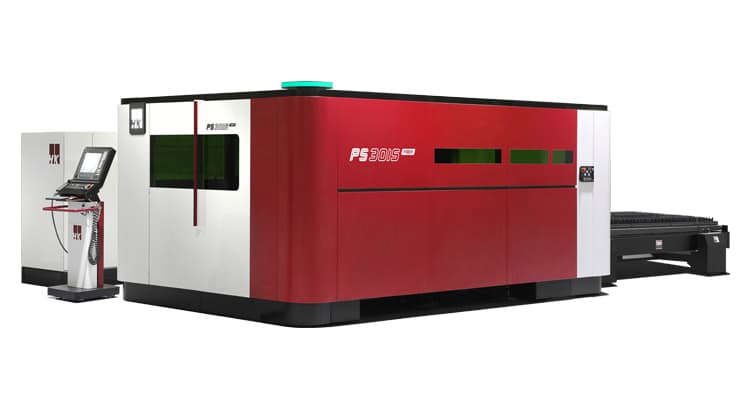

Fiber lasers are revolutionizing laser metal cutting industries with their low maintenance costs, high cutting efficiency and lower cost.