Cnc Beam Drill Line Design Guide

CNC Drill Line is a space-saving beam processing solution. It only takes up 70ft x 9.9ft. This makes it great for fabricators with limited space. CNC Drill Lines can also be placed outside, providing even more space for fabricators.

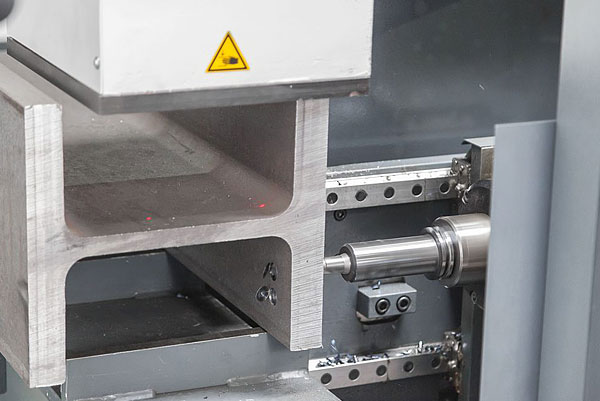

Continuous production? Check. The fabricator's edge does not come from the ability to just handle processes, but in the time it takes to complete them and simultaneously exceed industry standards for quality. Triple axis drilling and milling leads to processing a complete profile in record time. Powered by high-speed 25 horsepower Siemens spindle motors, this strength captures industry-leading hole penetration times and each drilling axis utilizes ball screw feed positioning. With all that power under the hood this drill line wields an advanced clamping system designed specifically to bring vibrations to the bare minimum. Extreme accuracy? Check.