Peddinghaus Ocean Avenger Manual

Based on the pricing at the various suppliers, we believe that the customer will be better off purchasing good quality Ocean Penetrator drill bits and a high quality sharpener.

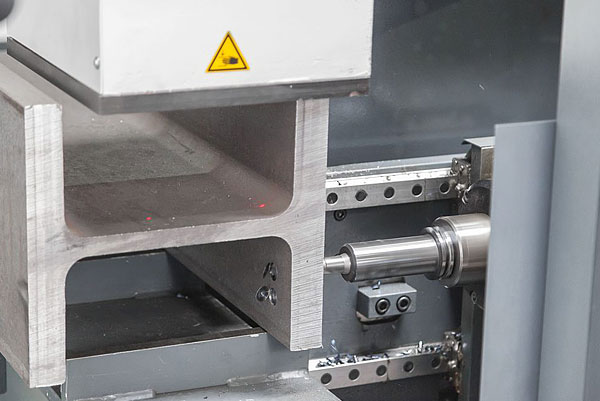

Advantage-2 carbide drills are equipped with electronic ball screw feed spindle motors and an automatic tool changer technology. Combining these features with Voortman�s well-known build quality as well as mechanical design, the result is a combination that combines agility and strength.