What causes beam failure

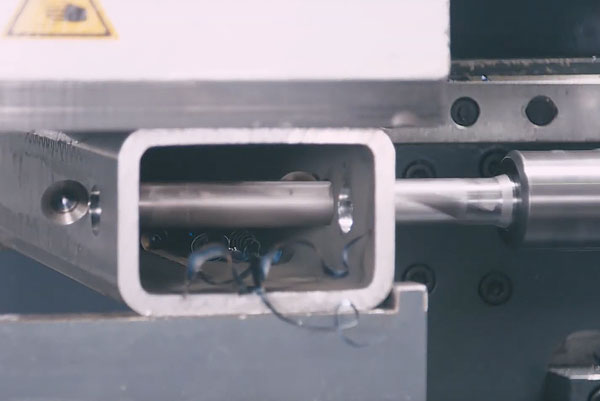

This range can ensure optimal productivity and excellent product outcomes. They perform outstanding functions like drilling, milling, marking, countersinking and thread tapping. All of these functions are designed to simplify your work processes.

"I believe without the help of the staff at GSS Machinery, we wouldn't be able to compete in the steel fabrication markets in which we are now competitive.