Cnc Beam Drill

Voortman�s 24 hour tech support center can resolve 90% of your support issues. An extensive network of 50+ Voortman personnel is stationed across North and South America.

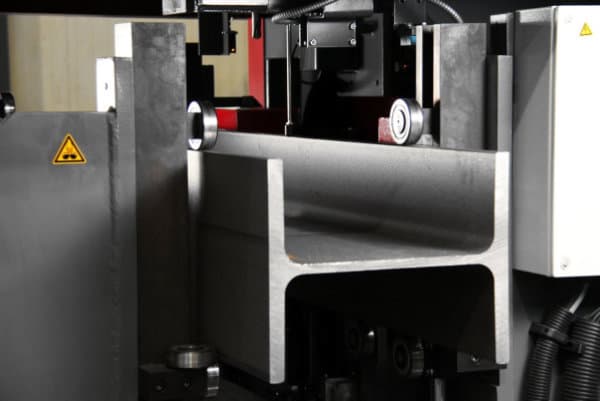

Voortman�s Roller Feed Measuring system surpasses industry standards in roller measurement technology. The key to accurate measurements is not allowing for any production hesitations. Even when there are material variations, accuracy must be maintained.