Can You Drill Through A Psl Beam

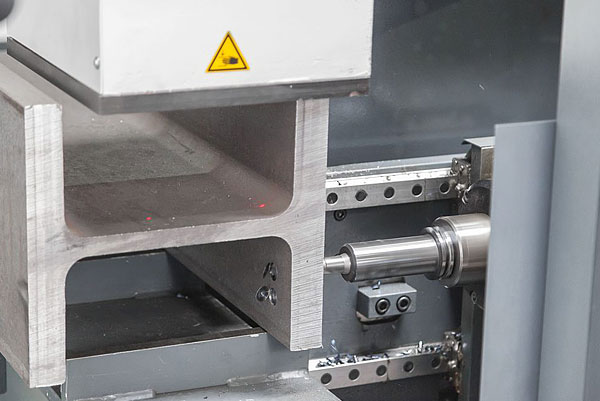

Renishaw Calibration 5 Axis - The calibrator is a Renishaw model APCA45 equipped with a modified spherical stilus. The device includes a retractable lid and an air purge to remove debris and dust during activation. It mounts to the swing arm, which is controlled by the pneumatic rotary.

Advantage-2 employs support clamps that ensure the best rigidity for the workpiece. Carbide tool lives are best maintained with as little vibration as is possible.