Cnc Beam Drill Line Up

AC Unit Mounted to Electrical Cabinet - This unit is mounted on the cabinet�s High Power (480v side). It is near the location where drives are mounted. This option allows for quicker heat dissipation, while keeping the cabinet temperature steady. The most significant heat contributors inside an electrical cabinet are all the servo motors for all axes.

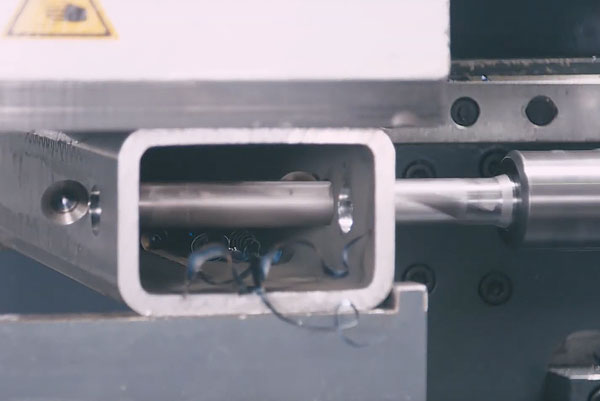

Voortman AccuMeasure Roller Feed measurement systems offer saw measurement options. AccuMeasure offers complete handling flexibility while providing a simple CNC solution. The ability to separate a drill from a saw means that neither machine has to wait for the other, maximising production.