Cnc Beam Drill Line Rankings

Importing files directly from steel detailing software is preferable. This eliminates the need for additional steps and eliminates any potential errors in data capture. In this regard, there are two distinct groups:

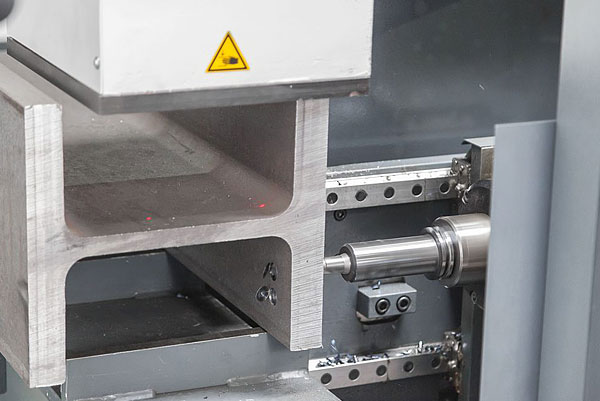

CNC Drill Lines are 100% hydraulic machines that make maintenance and parts very affordable. CNC Drilling Line was made to be used worldwide and only uses parts from major manufacturers. The majority of components can be found locally. Voortman maintains all parts in stock so that they can be delivered next day to the USA. In most countries that we serve, we offer local assistance and support.