Cnc Beam Drill Line Hotel

CNC Drill Line has the ability to import DXF files. They can then be used to produce 3-D shapes as long that the steel is prepared according to certain rules. These rules might not apply to what you are currently detailing. This may mean that some adjustments might be required. This process isn't as seamless as the 3D modeling software solutions.

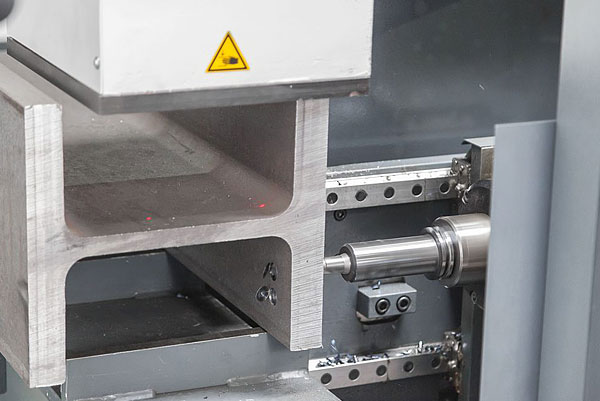

CNC Drill Lines can be used to drill holes in any type of material. CNC Drill Line was built to be universally used and therefore only utilizes components from top manufacturers. Many of these components can be obtained locally. Voortman always has spare parts available for next-day delivery within the USA. We offer support and local service in many of our overseas destinations.