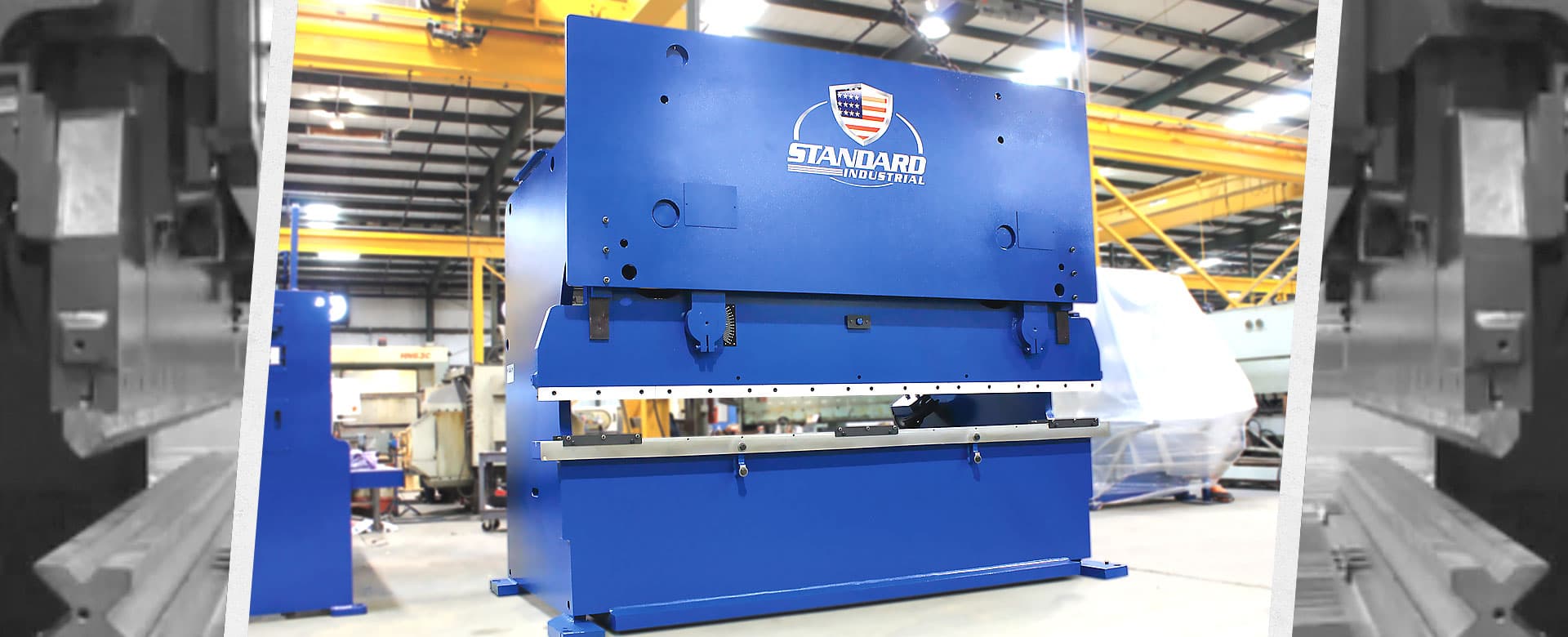

Single Cylinder Press Brake And

20' Press Brake

Gulf States Saw & Machine. Co. has a wide range of hydraulic press brake models that can be used to serve the diverse needs of all the businesses we service. Our press brakes are available in sizes from 22 tons up to 440 tonnes and can have beds lengths of 4' to 13'. We are able to accommodate special length requests and specific tonnage in addition to the standard stock. For easy and safe maintenance, all of our press brakes have safety devices. All electrical components are manufactured using industry-standard parts which can be easily found in our Memphis warehouse. Get more information about each model by downloading a pdf.

These machines are efficient and fast, and run more consistently than their predecessors.