Single Cylinder Press Brake High

Single Cylinder Press Brake And Wh

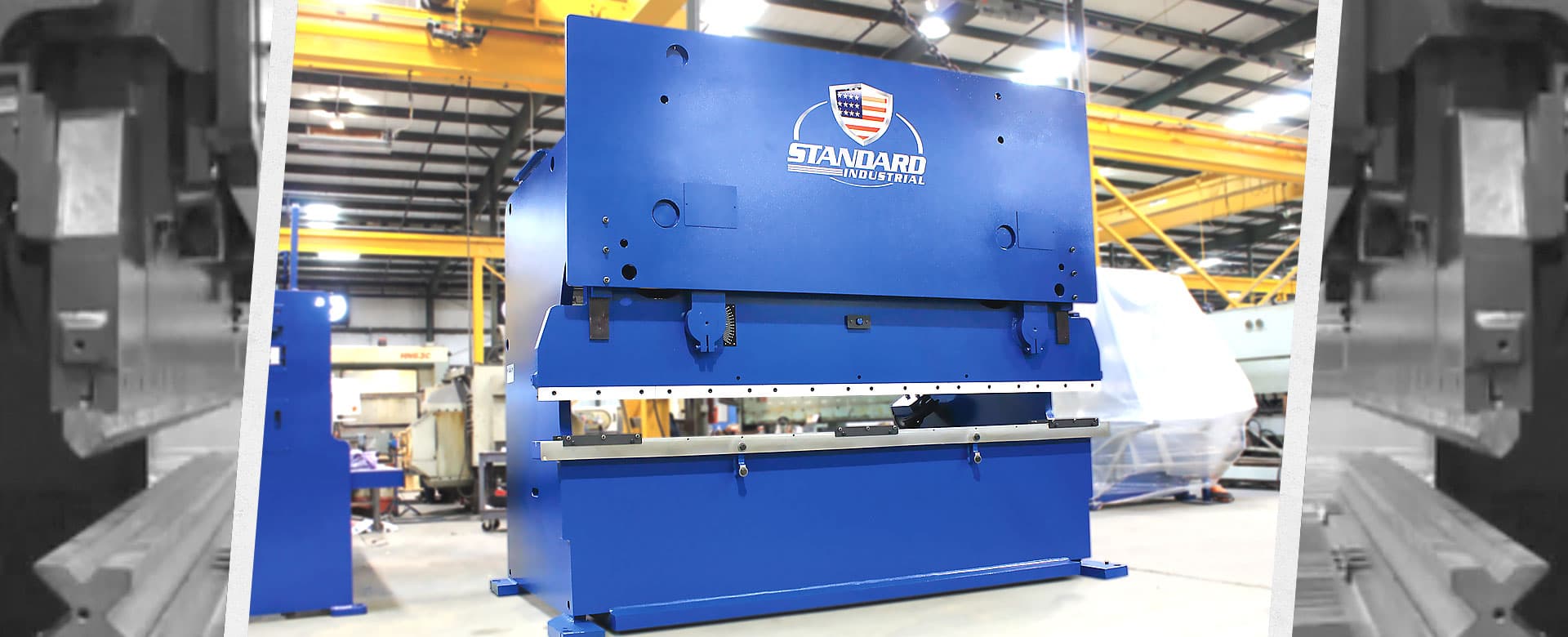

Day in and day out, Standard press brakes deliver the dependability and reliability your operation demands. Easy-to-use controls offer an unparalleled user-friendly approach. Our press brakes can handle a wide range of materials, including soft brass, heat-treated aluminum alloys, stainless steel, soft aluminum and chrome molybdenum.

What goes into a Piranha pressure brake? Our current models might be relatively new but we have been making press brakes for over a decade. We are proud to have created and engineered some outstanding machines like the single and dual-cylinder press braking systems that our customers still enjoy today. The U.S. steel prices were too expensive to fabricate. Our customers and dealers demanded that we build a new press brake shortly after we had stopped production. They loved the machine, and we made sure they were taken care of. They appreciated the fact that they could shop for and get service for any machine they owned in their shop.