Single Cylinder Press Brake Forum

Single Cylinder Press Brake Spacer

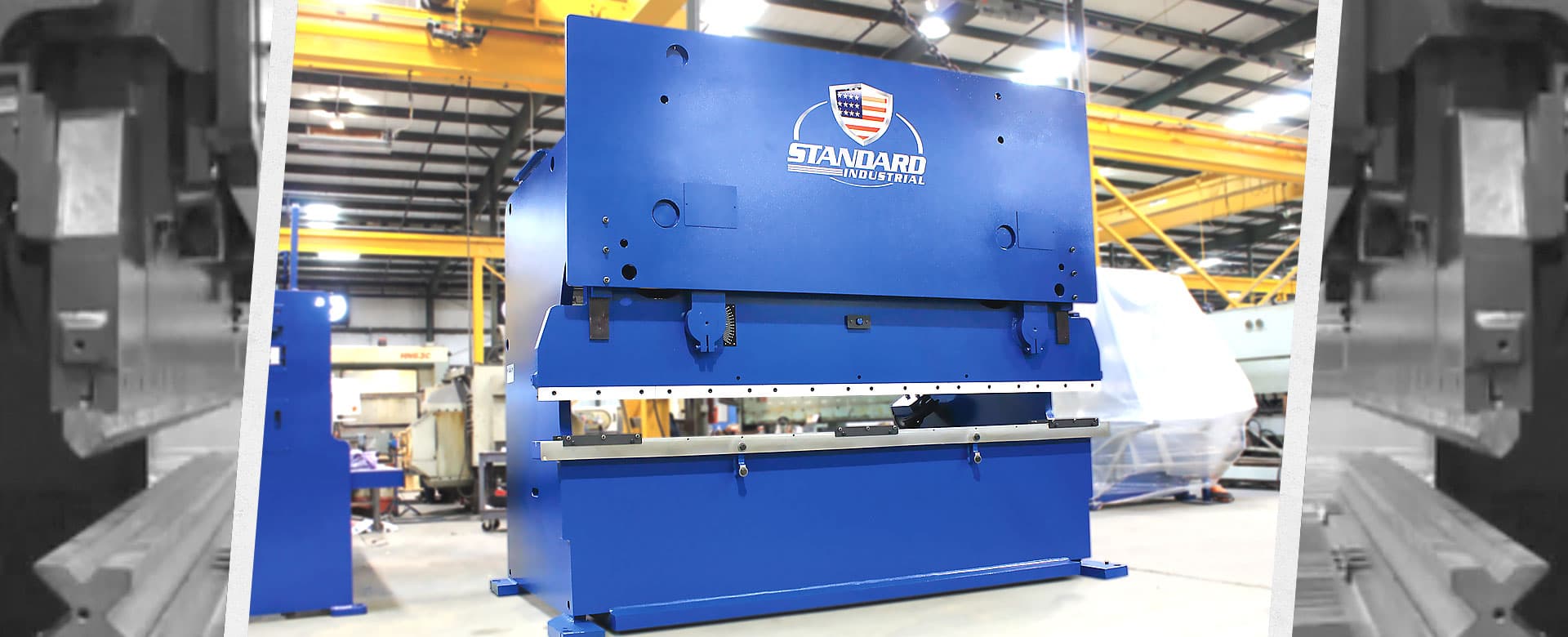

Intuitive operation, high productivity, heavy-duty bend performance, and high productivity all in one cost-effective package

Most press brakes are meant to be operated in the centre of the press. Standard Industrial press braking systems can handle off-center loading if there is significant force needed near the brake's ends.