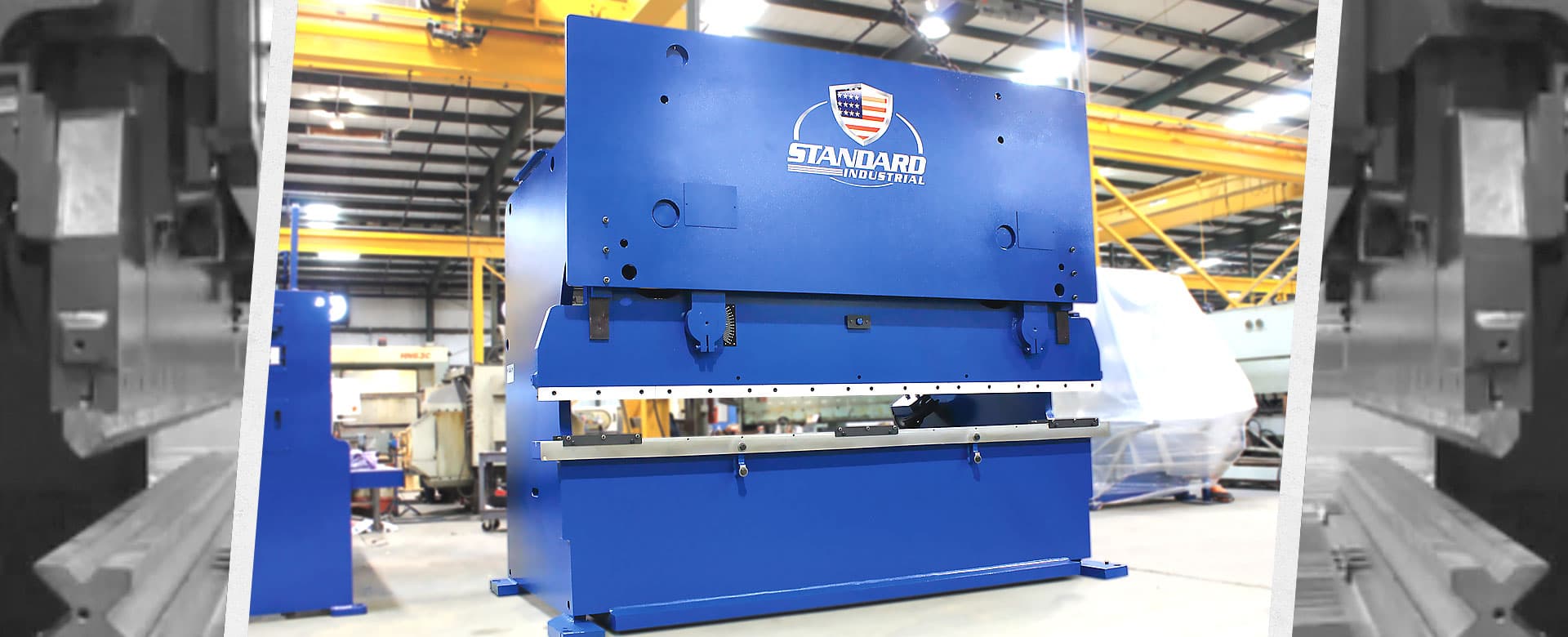

Single Cylinder Press Brake Guarding

High Repeatability

In air bending, the end of the punch and the 2 edges of the V allow the sheet metal to be bent. But this type of bending means there is a spring back effect of the work piece. As the bending force is weaker, the metal sheet springs backwards like an elastic when the punch is removed.

You will then need to determine what characteristics are to be considered when calculating a part bend. You can use the following examples:

Single Cylinder Press Brake Guarding