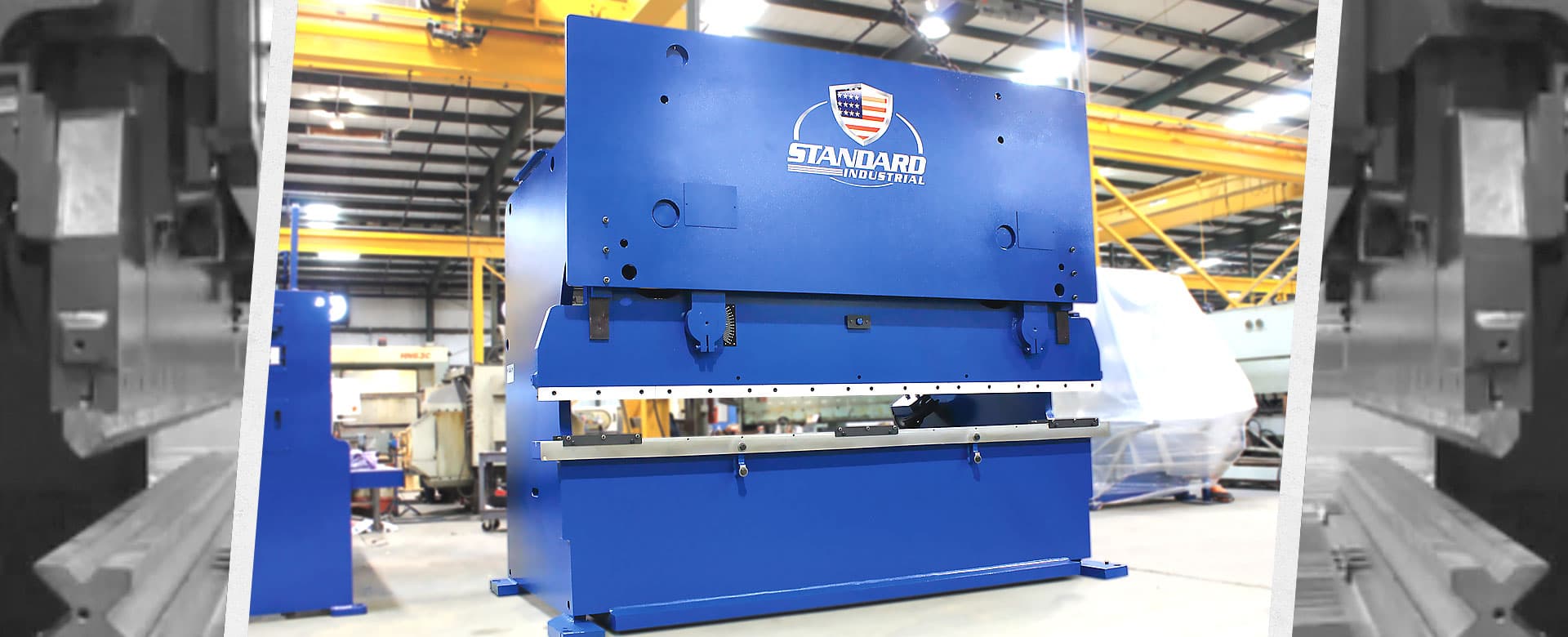

Single Cylinder Press Brake Dan

Single Cylinder Press Brake 4000

This game-changing tool allows press brake operators to work better than ever with real-time, accurate information.

The PA Plus series offers both functionality and versatility in a single package. The PA Plus series offers a variety of accessories that can be used to create a custom solution.