Single Cylinder Press Brake How

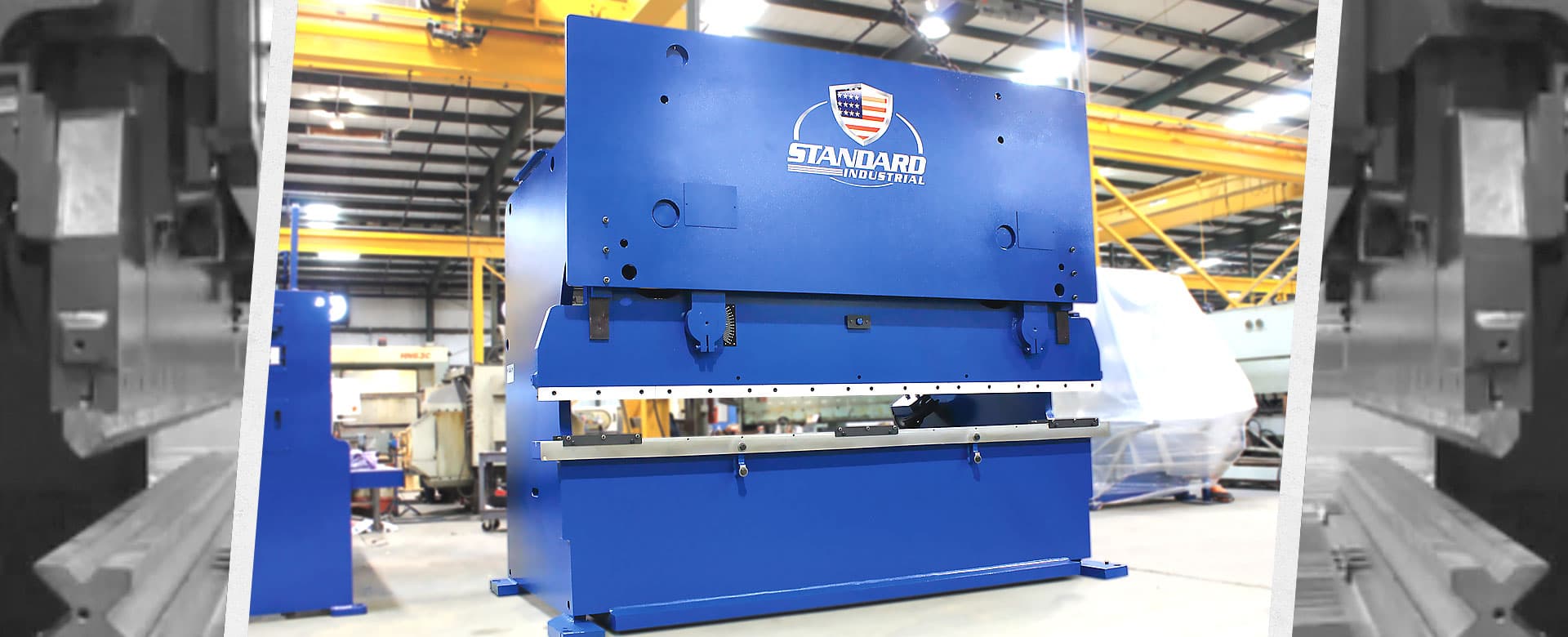

New Press Brake

A press brake is a machine tool used for bending metal parts and sheets up to 20 mm thick. It is composed of a V-shaped or U-shaped die (depending on the desired bending shape) and a punch. The material to be bent is placed on the die and pressed by the punch which then bends the sheet to the selected degree.

The motor inside a mechanical press brake operates via a motor. This motor spins an enormous flywheel at high speeds. The machine operator controls the flywheel via a clutch. A clutch then sets the other parts in motion and bends the metal. The mechanical press brake, with its electronic controls, is much simpler and makes maintenance and operation simple. A mechanical press brake can handle tonnages that are two to three times larger than their intrinsic rating due to its design. The downside to using mechanical press brakes, however, is that the machine's ram must complete its full cycle before it can be reversed. The operator can make mistakes, which could lead to safety concerns. A potential danger is that the press brake may become locked if it travels too far.