Single Cylinder Press Brake Harbor Freight

Single Cylinder Press Brake Operator

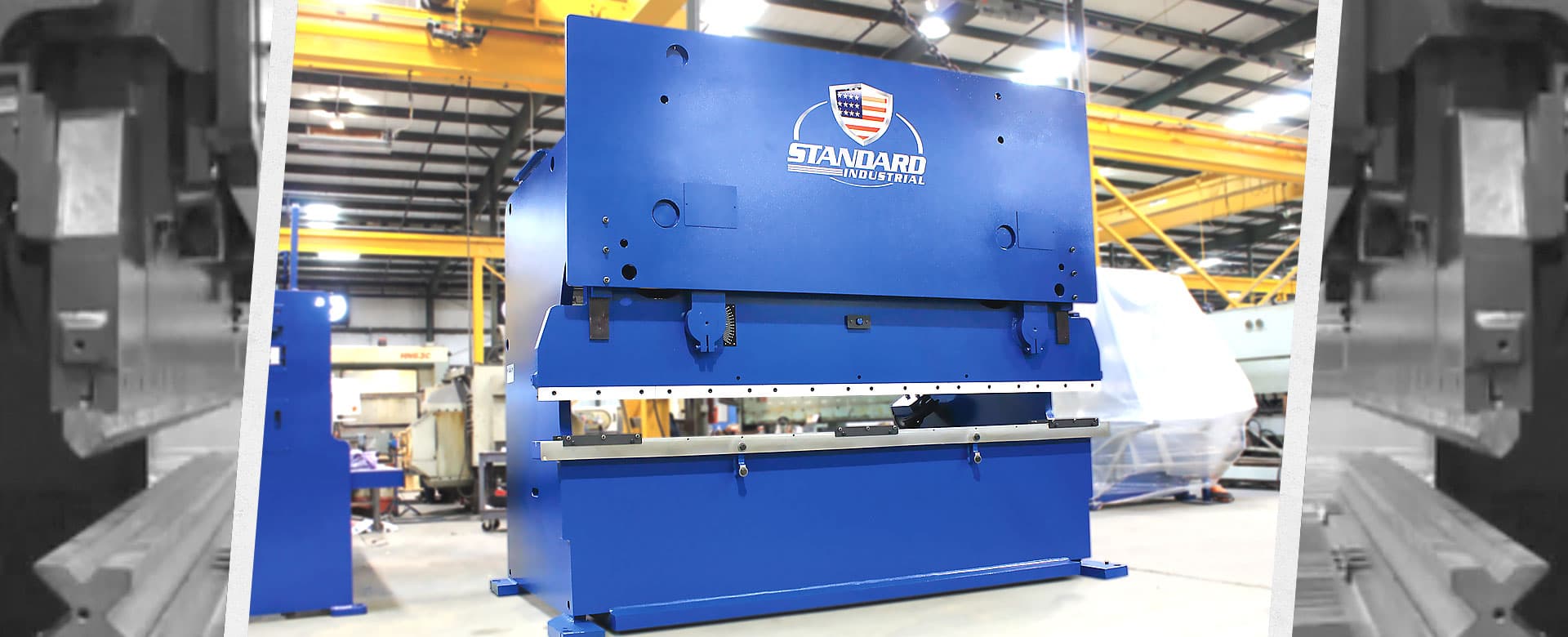

Standard Industrial offers a broad range of CNC gauges, starting with a single-line display and user-friendly controls all the way up to the highest level of 2D or 3D modeling. Standard equipment includes a press brake and a backgauge. To see a complete selection of systems, please visit our separate CNC Controls and Gauging catalogue.

This method provides a high level of angular precision.It is suitable for sheet metal over 2 mm thick.

Single Cylinder Press Brake Harbor Freight