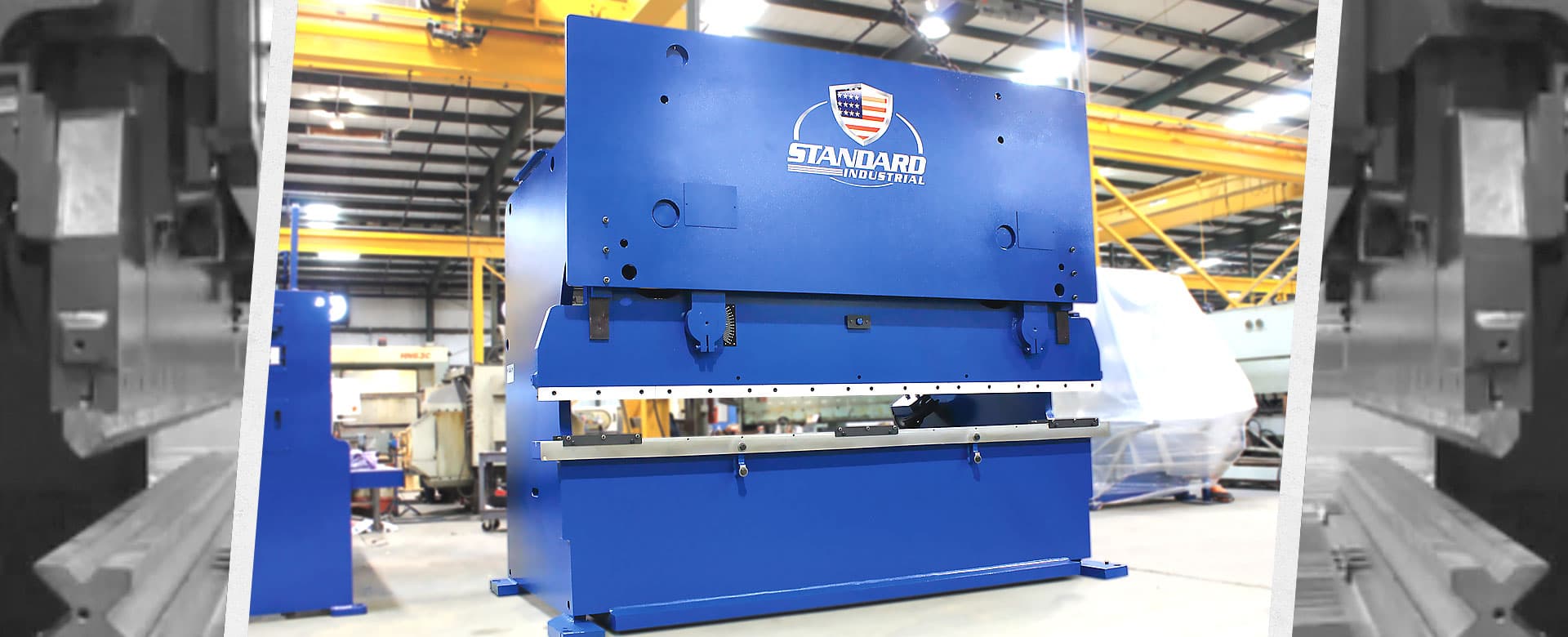

Single Cylinder Press Brake Excell

Single Phase Hydraulic Press Brake

A press brake can be described as a machine tool that is used to bend metal parts or sheets up to 20mm thick. It's composed of a U or V-shaped punch and a die. The material to be bent can be placed on the die and then pressed by the punch. This bends the sheet to a desired degree.

Our energy-efficient, all-electric BB series press brakes come specially designed with a collection of ultra-modern, performance-enhancing features that are perfect for meeting and exceeding the demanding requirements facing today's production machinery experts.