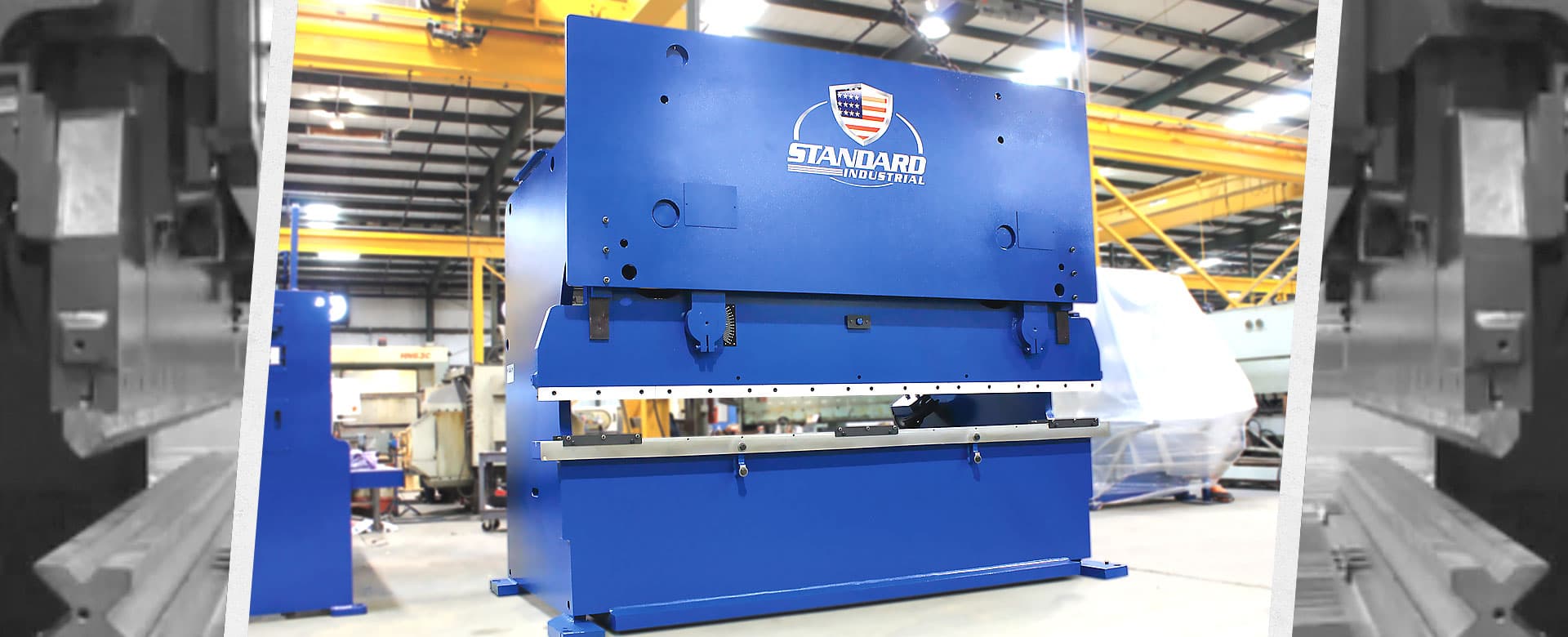

Single Cylinder Press Brake in Alabama

Single Cylinder Press Brake Tonnage Calculator

The majority of press brakes are intended to work in the center of the presses. When there is a lot of force required near the brake's ends, Standard Industrial press brakes will apply off-center load.

There are two methods that press brakes can bend steel. The first, or bottom bending, is when the ram presses metal to the bottom. Bottom bending can produce precise bends and is less dependent on the press brake. The problem is that each tool is designed for a specific type of bend. You will need to purchase a brand new tool for each angle. Air bending creates an air pocket between the die's bottom and the ram. This allows the operator flexibility in accommodating any spring back provided by the material. These types are only necessary to be replaced if the material is too thick. The drawback of air bending is its inability to accurately bend the material. This means that the ram will need to be changed accordingly.

Single Cylinder Press Brake in Alabama