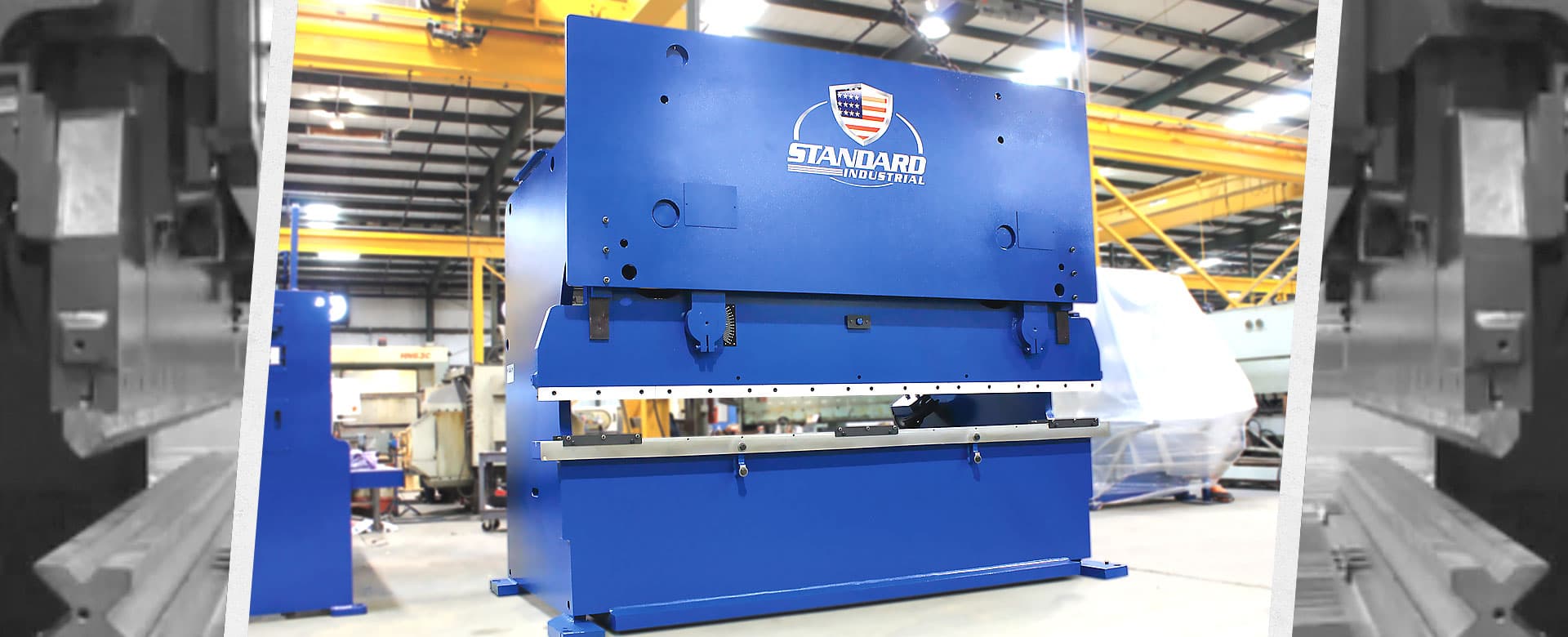

Imagine giant, intelligent, large press brakes with a vast range of tonnages, lengths, loading/unloading metal material handling and an infinite number of bending lengths. Our high tonnage mega presses brakes feature an advanced engineered technology "box-construction" frame design. This gives our mega brakes one of the strongest and most stable machines in the world. All of our references around the globe are impressed by the exceptional stability and rigidity that our large high tonnage presses brakes have, thanks to our box-construction frame design. Our high tonnage presses are designed to minimize large pieces being handled before, during, or after the bending operation. This allows for the next process to be respected.

It has a double axis servo-electric back gauge system. It is capable of automatic bending step calculation as well as lengths that are full between side frames. These servoelectric presses are easy to use, precise, and cost-effective.