Single Cylinder Press Brake Gear

Single Cylinder Press Brake Quiz

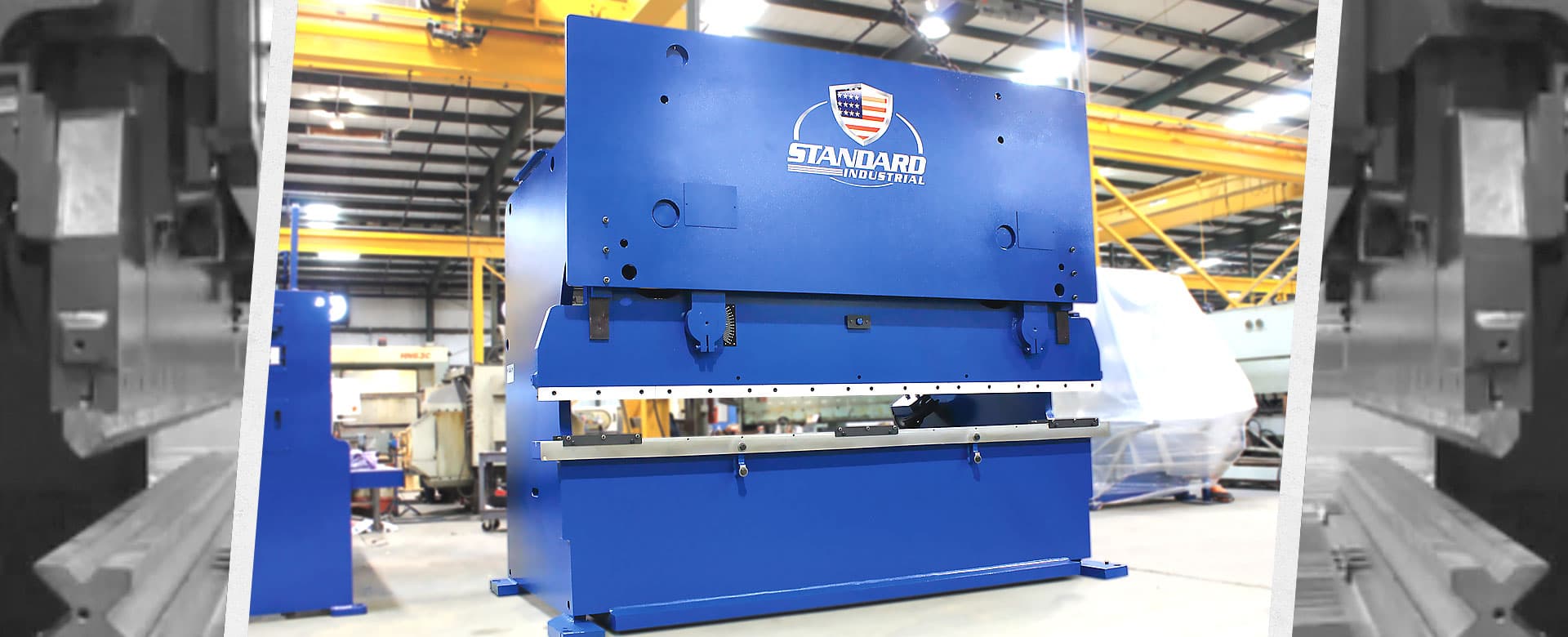

No matter what kind of bending you need, our BH series will be there to meet your needs.

Gulf States Saw & Machine. Co is a Member in good standing of the American Welding Society.