Cnc

GSS Machinery�s magnetic brush and broom help with the removal of chips from the machine and for sweeping up chips from the floor

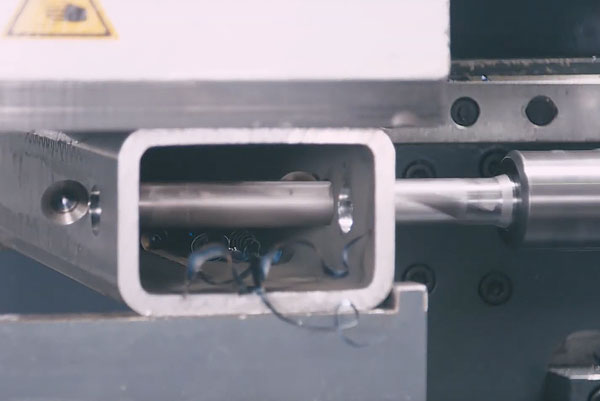

"..We have drilled about 25,000 holes since we bought our CNC Drill Line around four months back. We used to need to drill every hole in 5 minutes. It takes us about. 30 seconds per hole = a savings totaling 1875 manhours in just 4 months. This saves us $84,375. This machine will pay for its cost in less that one year. It speeds up our production and frees up floor space to allow for additional jobs.