Cnc Drilling Line In India

The CNC Drill Line can import DXF files and can use them to process 3-D shapes as long as the steel is detailed according to specific rules. Some of these rules might be different to the way you are detailing at the moment and might require some adjustment. This process is not nearly as seamless as the 3-D modeling software solutions above.

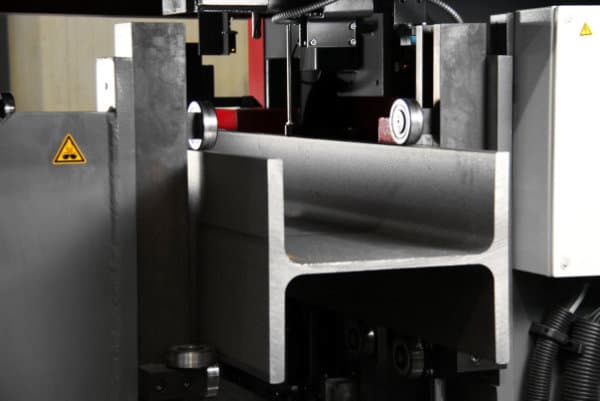

The CNC Drill Line is built exclusively for GSS Machinery by Voortman. Voortman handles the installation, warranty and service work on the CNC Drill Line. And while Voortman is the service provider, GSS Machinery is always there to get involved should the need arise.