Cnc Drill Line Jefferson

Gulf States Saw & Machine Co. has a Drill Line or Beam Drill Line that will suit every fabricator. We also have Beam drills for those who have limited work space.

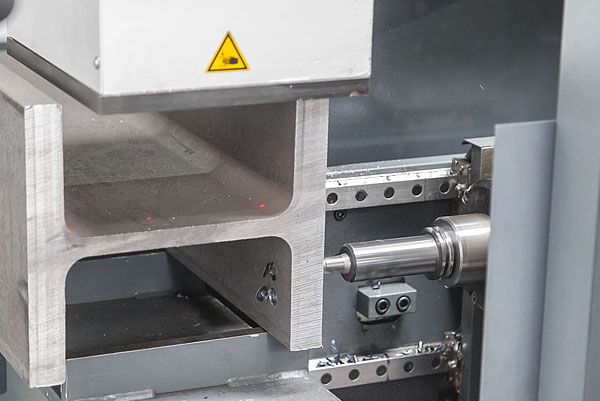

Automatic Edge Finder - The edge locater can be used either manually (Jogging Mechanism & Screen Buttons), programmatically or completely automated (dedicated programs). This option adjusts the offsets and rotation of the program to match the cutting table's orientation.