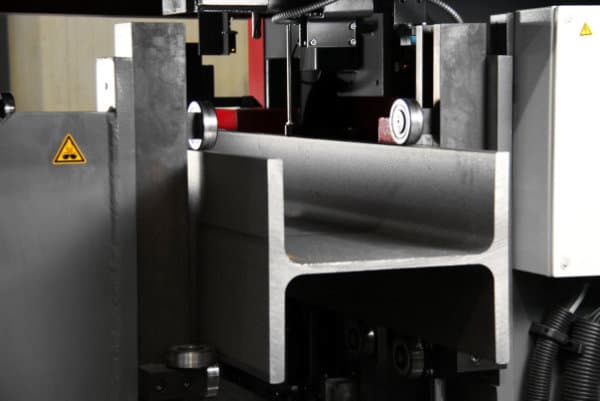

Cnc Drill Line Wis

This Morse Taper chuck adaptor permits you to use standard parallel shank drilling bits for smaller diameters. It has a maximum drilling diameter of 12mm. (12mm) and a minimum drill diameter of 3/64 (1mm).

We have installed over a thousand CNC Drill Lines and Angle Lines around the globe and have found that even a novice programmer can be proficient on the machine in less time than half an hour.