Cnc Drill Line Lyrics

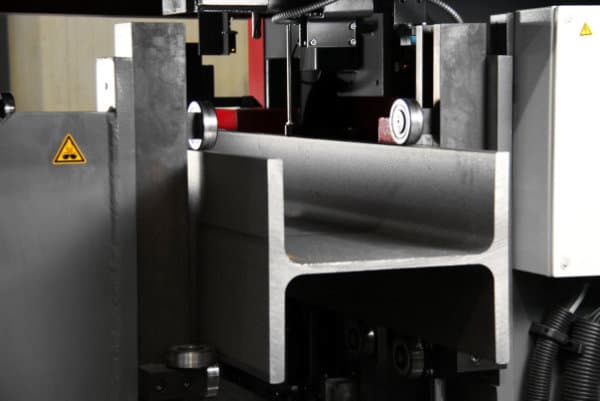

Voortman has designed the CNC Drill Line exclusively for GSS Machinery. Voortman is responsible for the installation, warranty, and service of the CNC Drill Line. Voortman handles the installation, warranty and service work on the CNC Drill Line. However, GSS Machinery is always available to assist if necessary.

Voortman's Raptor 3DCAD/CAM Software is a revolutionary tool that allows users to program CNC faster and more accurately. You can view, modify and export parts information right from the 3D platform. This technology is combined with Voortman CNC technology gives fabricators maximum productivity.