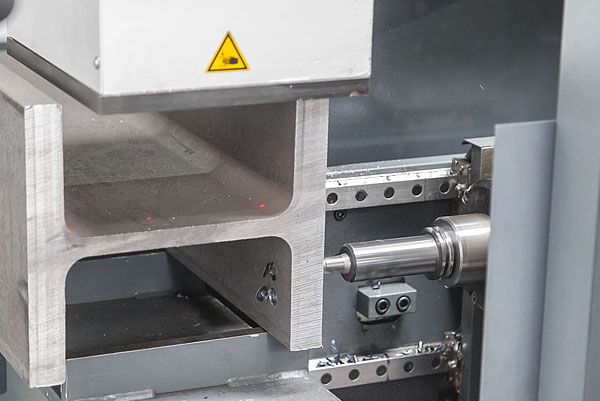

Indicating A Drill On A Cnc Lathe

Voortman is the only manufacturer of the CNC Drill Line for GSS Machinery. Voortman takes care of all aspects of the CNC Drill Line's installation, warranty, maintenance and repair. Voortman provides the service, but GSS Machinery can always be reached if required.

It is better to import files directly form your steel detailing program. This removes an unnecessary step as well as eliminates potential incorrect data capture. Two distinct camps exist in this regard: