Cnc Drill Line Road

The CNC Drill Line can be operated easily and Avenger operators are the ones who lay out the floor. You don't need any prior computer knowledge and are given full training at the time of installation.

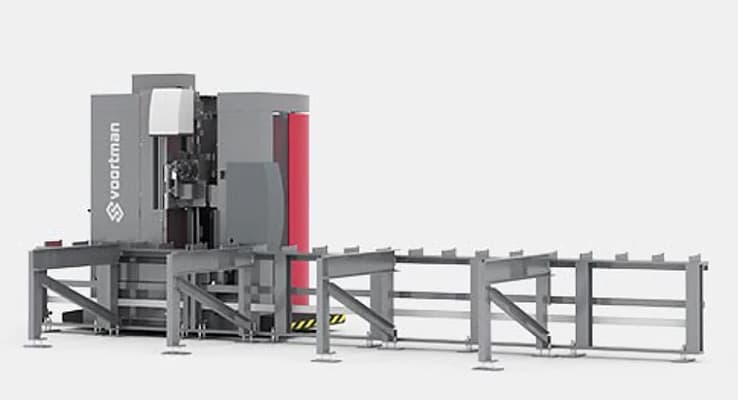

CNC Drill Line is 100% hydraulic, making it extremely affordable to maintain and purchase parts. CNC Drill Line is a 100% hydraulic machine that was specifically designed for worldwide use. It uses components from the major manufacturers. Most of these parts can be found in local markets. Voortman stocks all parts for next-day delivery in the USA. We offer support and service in most of our overseas locations.