Cincinnati Hydraulic Press Brakes

Circuit

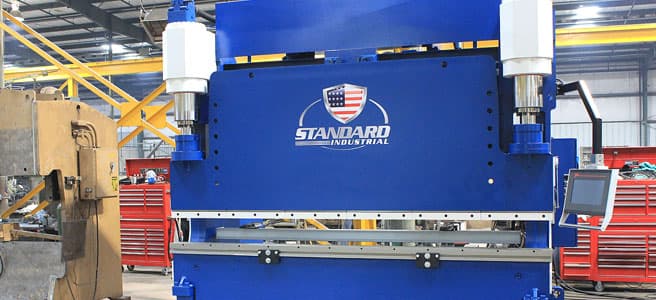

This dual-drive hybrid can be used to quickly complete any project. It is long-term and high-speed as well as energy-efficient.

Standard is supported and assisted by an expanding group of industry professionals. This includes experienced application engineers as well as product specialists and sales consultants. JMT also offers a tooling and parts department that will ensure your machines are running at maximum performance.