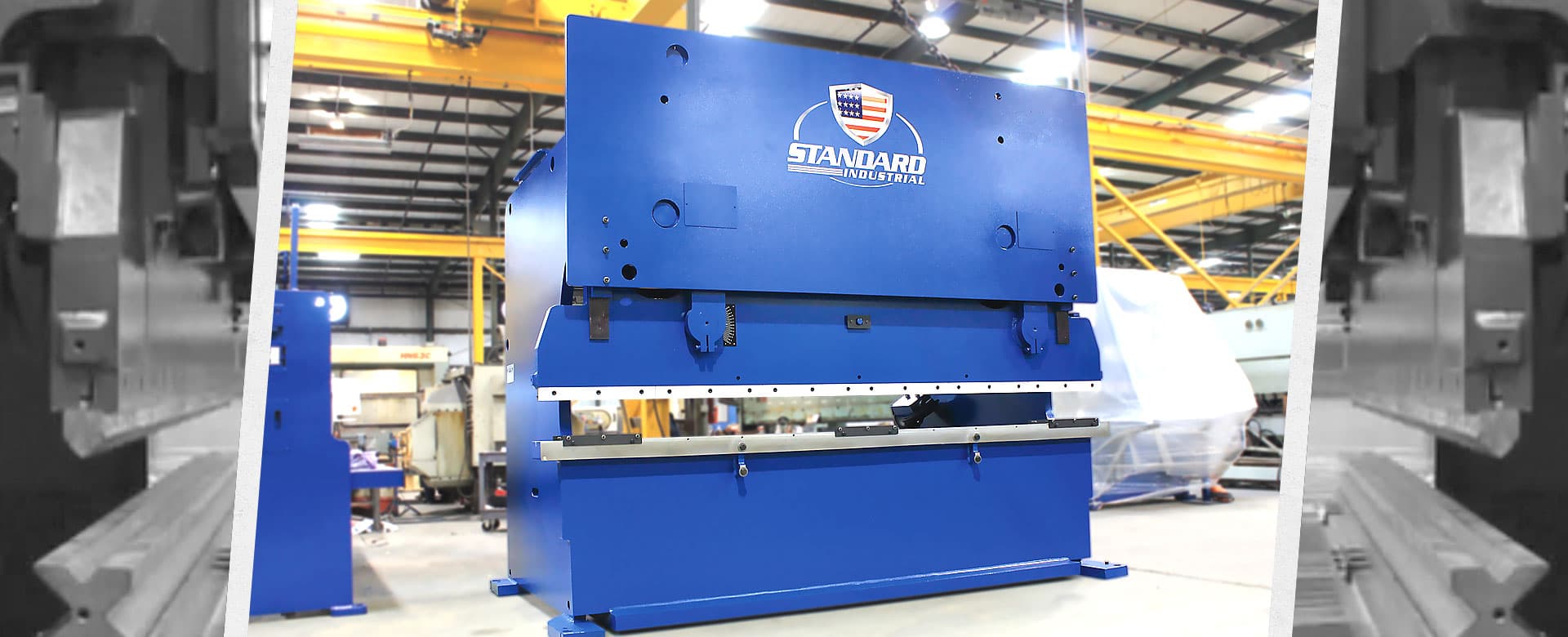

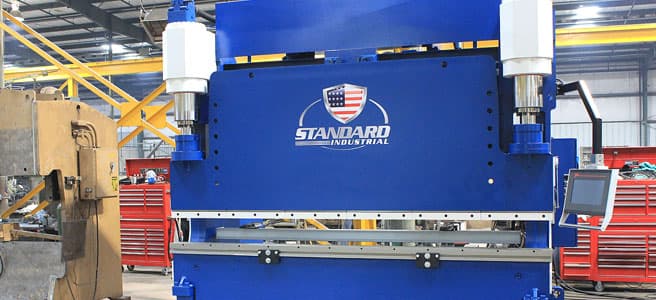

Cnc Hydraulic Press Brake Bending Machine Price

Metal Bender

This method offers high levels of precision and angular accuracy. This method is ideal for sheet metal with a thickness of more than 2 mm.

You should also consider other factors when calculating this margin. These include the thickness of your punch blade and the length of the fold.