Hydraulic Press Brakes Jumper

Folding Machine

Next, determine the specific characteristics that must be taken into consideration when calculating the bend. You will need to consider the following:

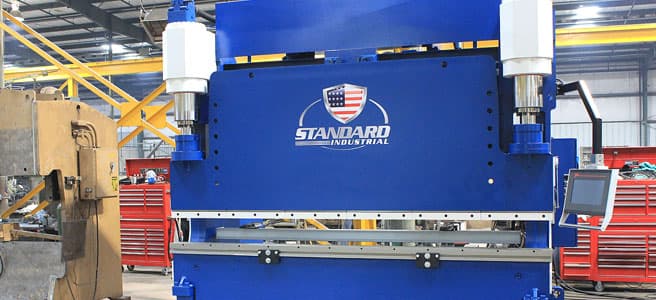

Gulf States Saw & Machine. Co. offers a wide selection of hydraulic presses to meet the specific needs of every business we serve. Our press brakes can be adjusted to any length bed, with either CNC or manual controls. They are available in sizes ranging from 22 tons to 440tons and bed lengths ranging from 4' up to 13'. We are also able to accept custom orders, including length and tonnage requests. All our press brakes are equipped with safety devices, and a rear safety box that deactivates the machine when it is opened. This prevents any unauthorised maintenance. All electrical components are constructed using industry-standard parts. These parts can be readily found in our Memphis TN warehouse. You can download the pdf to see more details about each model.