Hydraulic Press Brake For Sale Canada

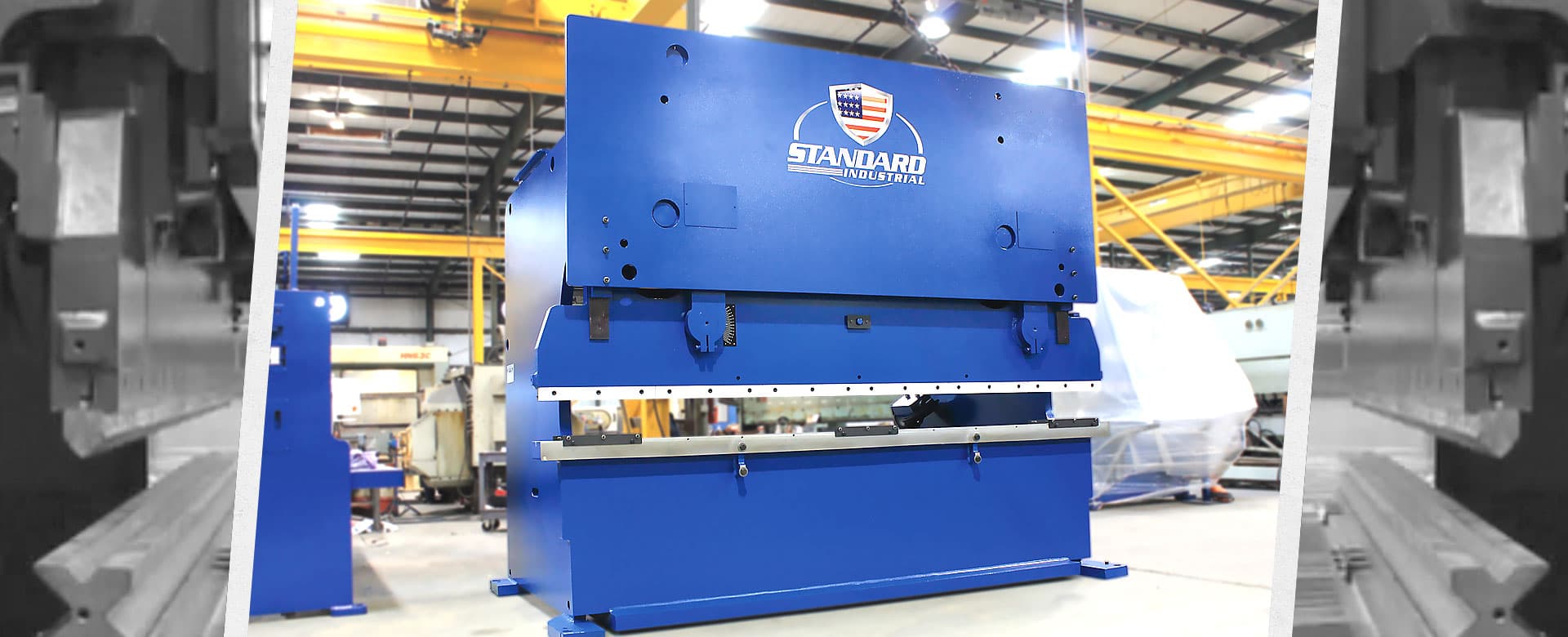

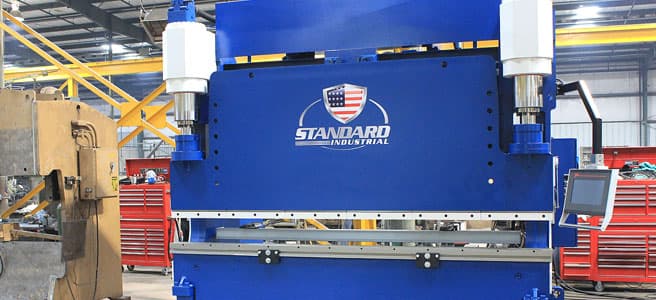

Hydraulic Press Brakes

Optimize your workflow to reduce time, money and human effort. You can avoid costly downtime and product defect. You can fine-tune your shop to meet changing needs with unrivalled programmability, functionality and cloud-based machine insight. There is an automation solution for every challenge.

Warning! Incorrect tonnage can damage your press brakes or the parts you are bending. Refer to the operator manual or to a tonnage tables to determine the tonnage on your press brake.