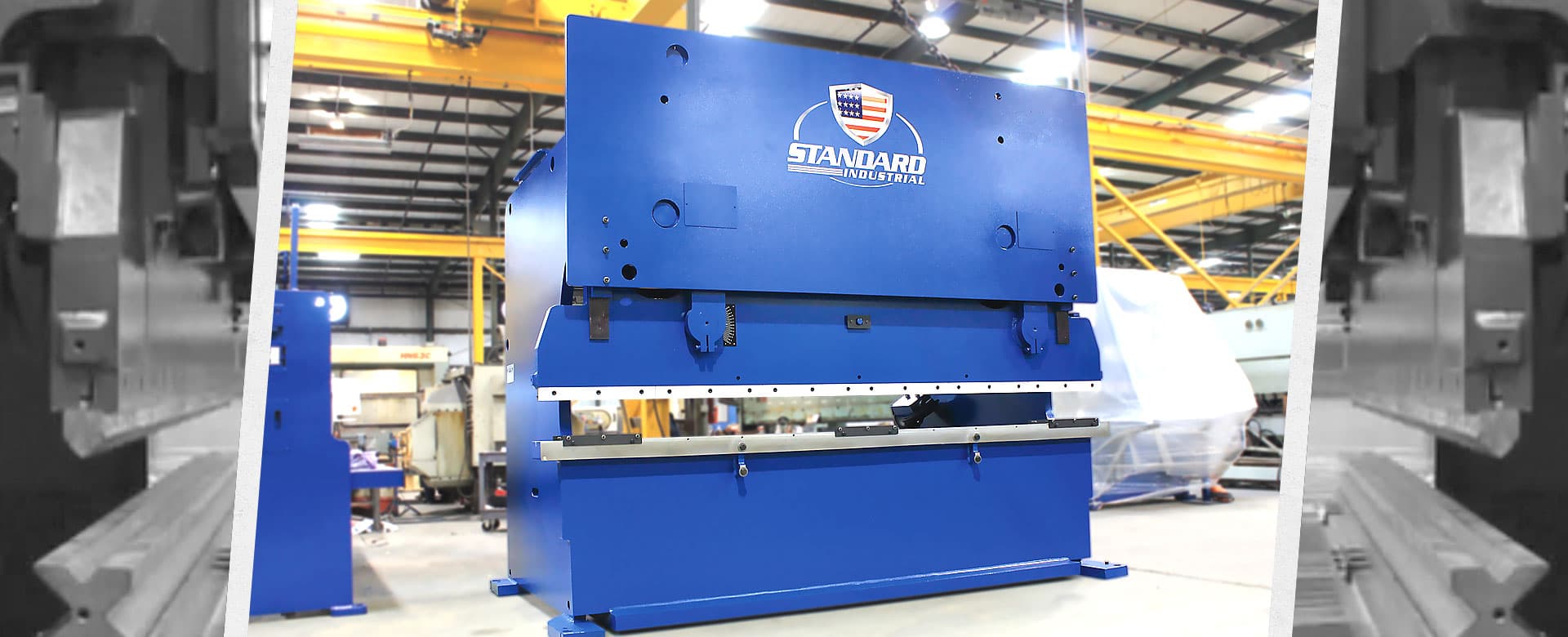

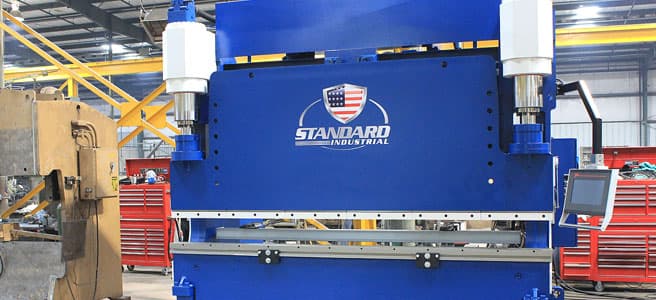

Hydraulic E Brake Kit

Hydraulic Press Brakes 5000

Flexible and reliable bending performance thanks to the patented HEXA�-C(r), frame - all in a compact package.

We also have a range of Press Brakes designed on the hydraulic control system. Its bending capacity is capable of handling thick work-pieces. As a result of its tonnage capacity, it works efficiently on any thick metal material. This range is built in either Single Cylinder or Dual Cylinder Y1+Y2 formats and requires no complex operation to function. Materials that can be processed on our Press Brakes include steel, brass, metal sheets, and aluminum alloys.