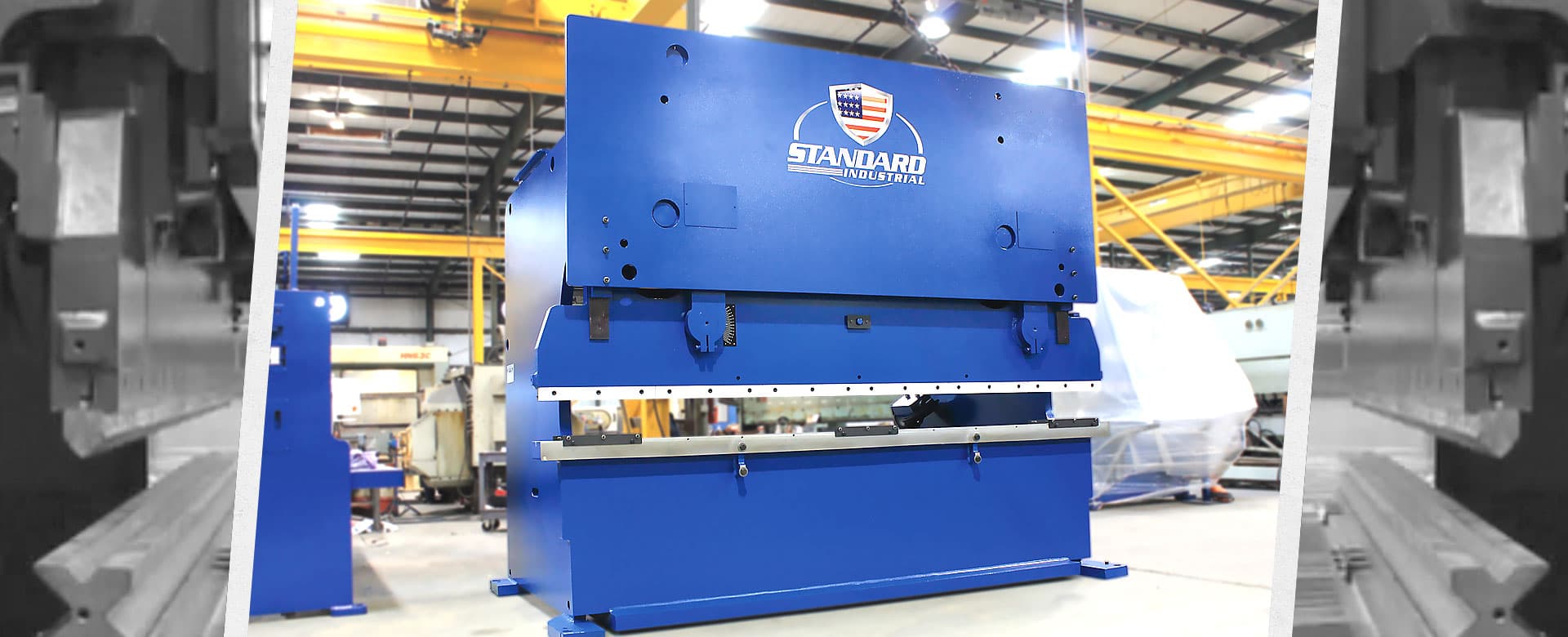

Hydraulic Press Brakes Maintenance

H Frame

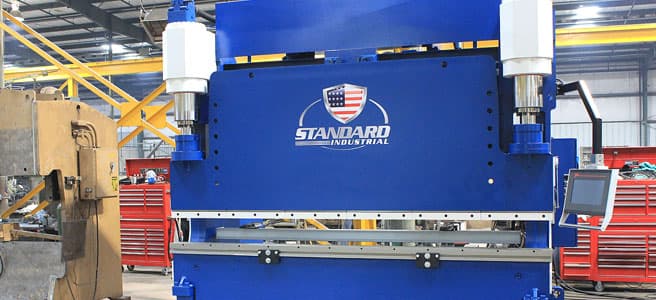

The BH Series "hybrid press brakes" prove that hybrid press brakes do not always work the same. These third-generation machines use their dual-drive design to offer the best of both electric and hydraulic bending: high productivity, precision movement, reliability, and superior savings - even when compared with other hydraulic, electric pulley, and hybrid press brakes.

Flexible and reliable bending performances with the patented HEXA (r) frame � all this in a cost-efficient package