Two methods can press brakes bend steel. The first is bottom bending, where the ram presses the metal to its bottom. Bottom bending allows for precise bends, and less reliance on the machine's press brake. Each tool has its limitations. They are designed to create a particular bend and you will need a different one for each angle. The bottom of the die and the ram are separated by an air pocket when air bending occurs. This allows for the operator to account for any material spring back. These types of dies need to only be changed if there is excessive material thickness. Air bending has a drawback. Because the thickness of the material can affect the accuracy, the ram needs changing accordingly.

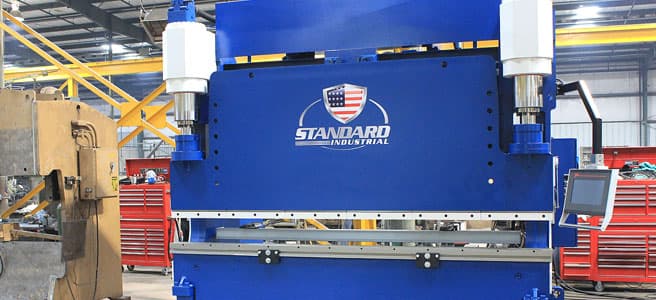

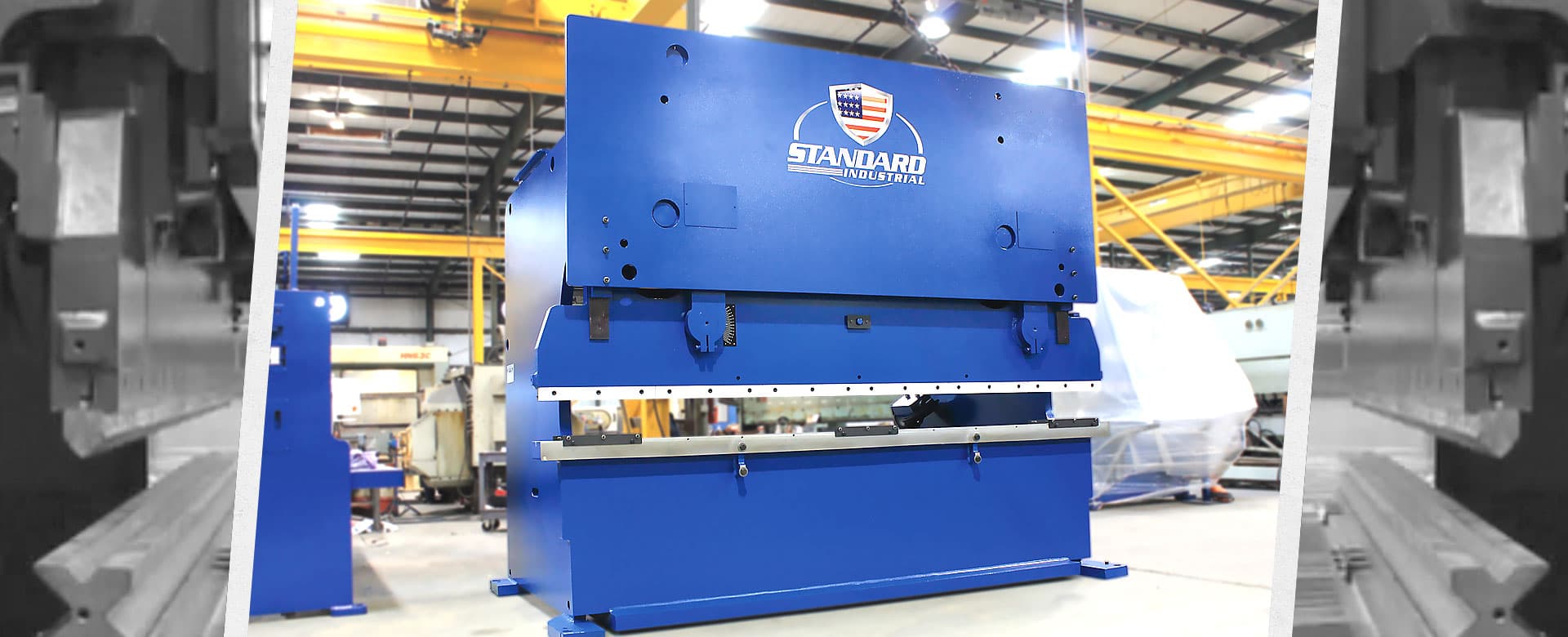

Our energy-efficient, all-electric BB series press brakes come specially designed with a collection of ultra-modern, performance-enhancing features that are perfect for meeting and exceeding the demanding requirements facing today�s production machinery experts.