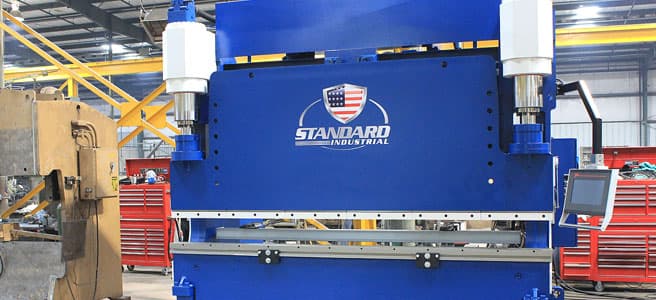

Hydraulic Press Brake Hydraulic

Ton Hydraulic

The use of press brakes is common in sheet metal and production plants in many areas, including automotive and aeronautic.

The CNC technology system-the Computerized Numeric Control, is used to create our single and dual cylinder Hydraulic Press Brakes. Our advanced dual bending machines work solely electrically because they are run on Servo Electric systems. They don't need hydraulic oiling and require minimal energy.