I Have To Press Hard On Brakes

Hydraulic Press Brakes Maintenance

The tonnage is the press force of the press brake. It determines the amount of pressure that can be applied by the punch during the bending operation.

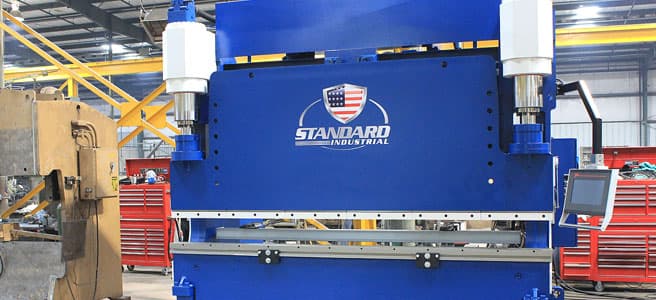

Hydraulic presse brakes are great for heavy-duty tasks and can be customized to suit any customer's needs.