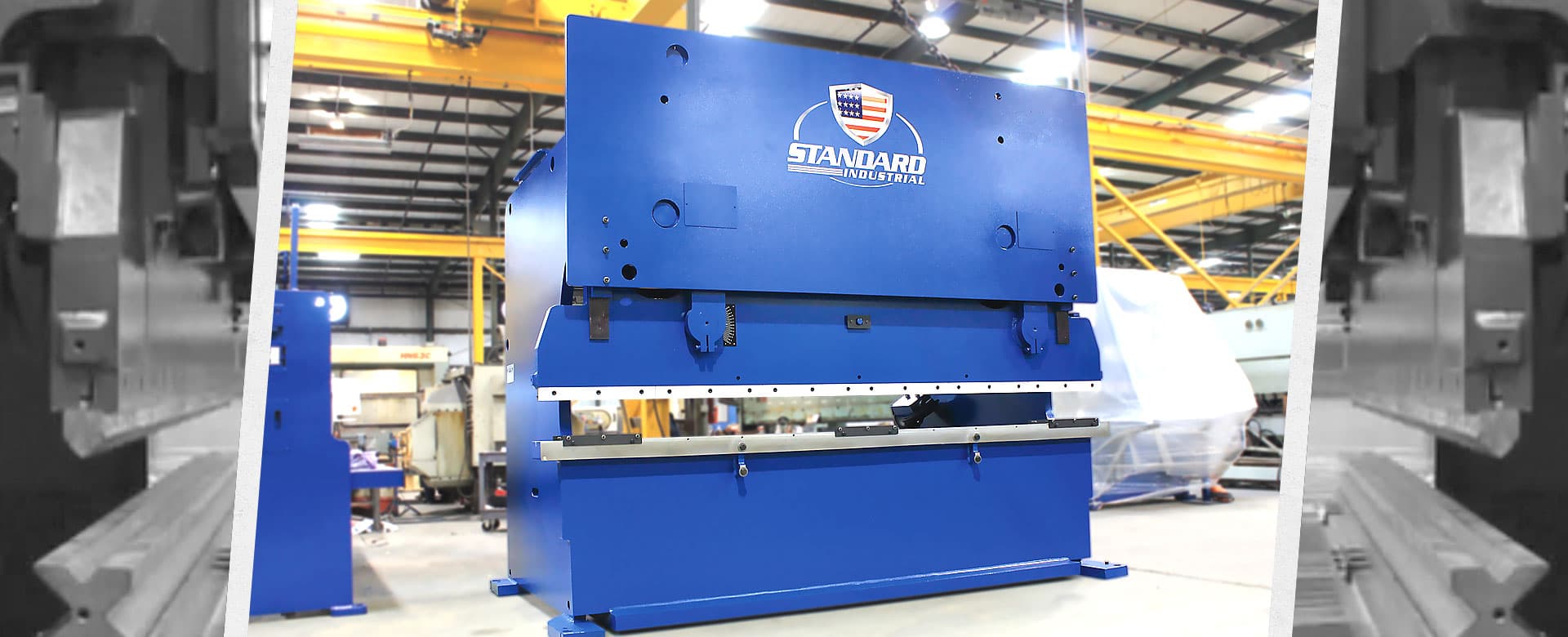

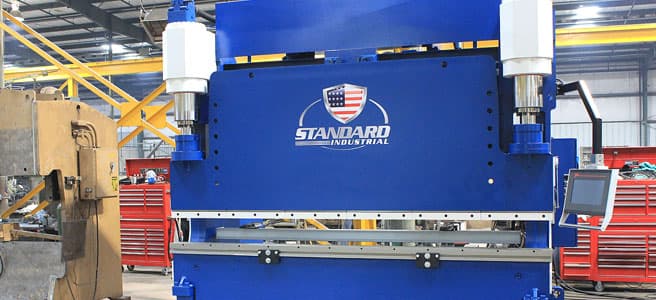

Hydraulic Press Brake Design

Is It Brake Press Or Press Brake

The bending angle must be adjusted according to the metal springback and the margin must also be calculated. For example, a 90deg bend requires that the punch be lowered to 85deg.

Standard press brakes have the reliability and dependability that your operation requires. A user-friendly interface and controls provide an unbeatable level of convenience. Our press brakes can handle many materials, including soft Brass, heat-treated Aluminum Alloys, stainless Steel, soft Aluminium, and chrome molybdenum.