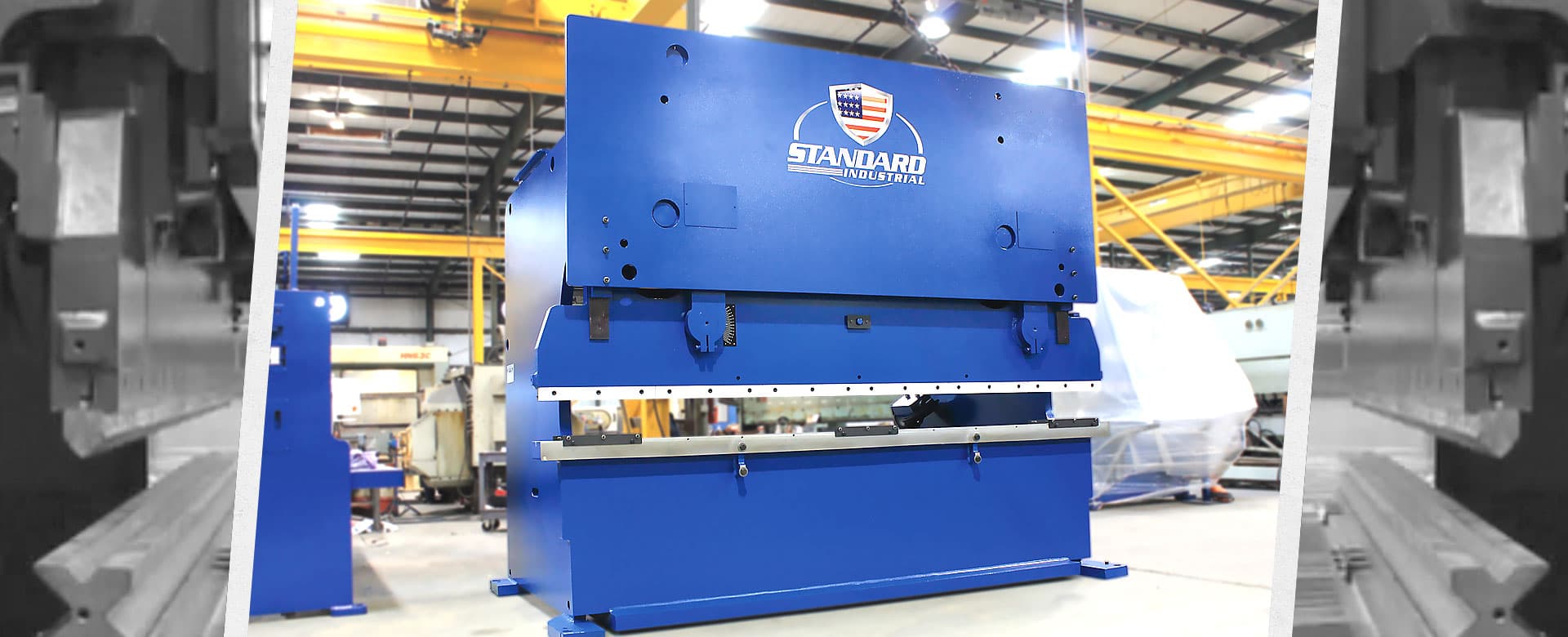

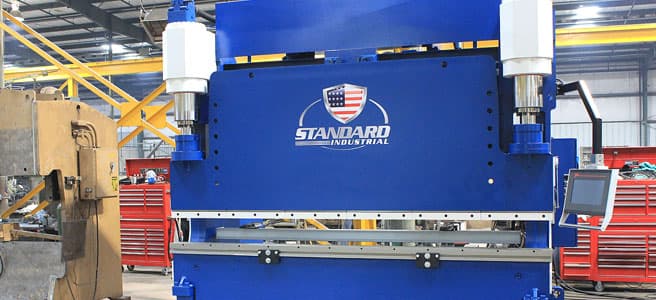

Hydraulic Press Brake Machine Specification

Backgauge

Our CNC control hydraulic press brakes offer users the ability to tackle any project with precision, speed, and volume. These machines can handle the most demanding jobs with impeccable details. The capability to use a removable USB drive means that additional program storage is virtually limitless. Other key features include:

Whatever your bending needs, our BH series is here to make sure that power, precision, and profit are never far away.

Hydraulic Press Brake Machine Specification