Hydraulic Press Brake Risk Assessment

Pressure Gauge

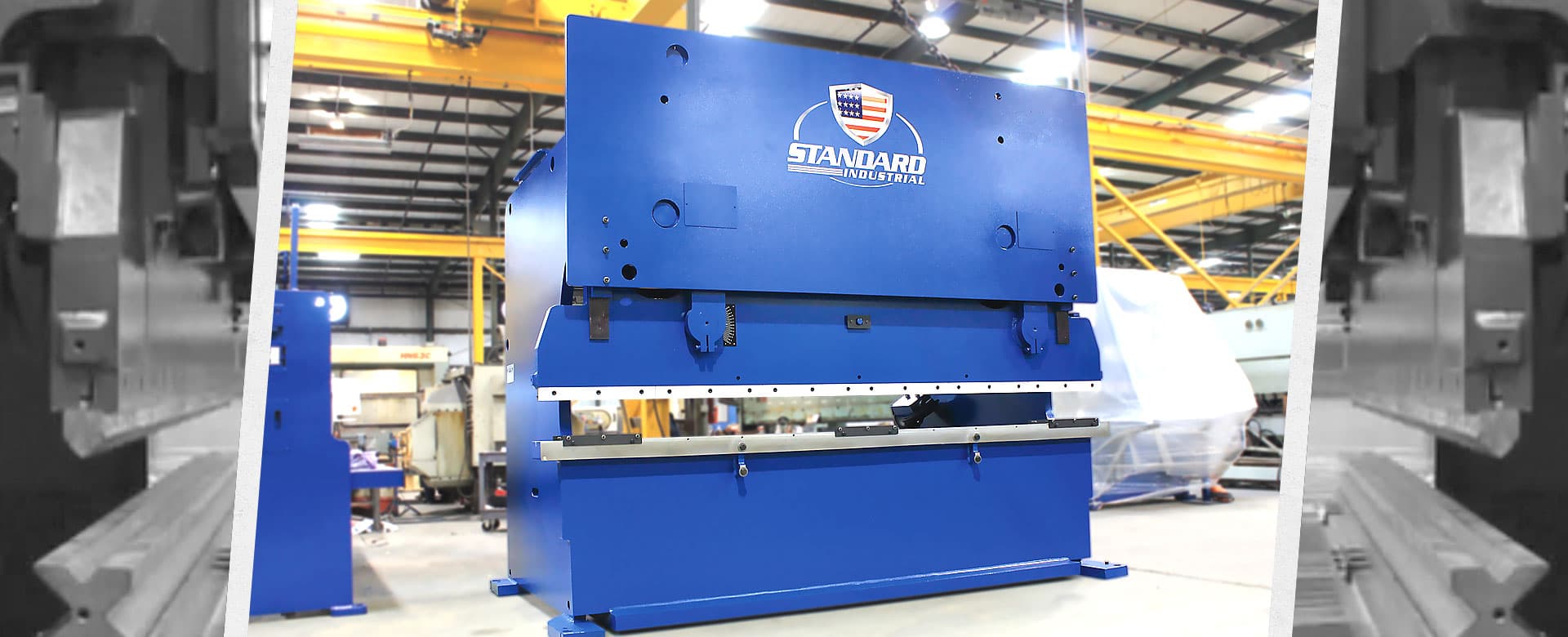

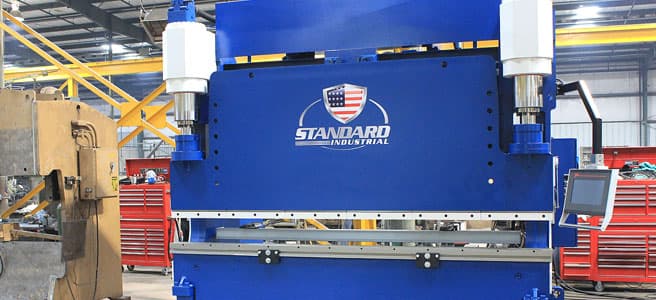

It is said that the "little guys" sometimes punch higher than their weight classes. Our small, 4-foot press brake is an example of this. The compact bender includes a CNC-controlled X-axis back gauge, tangs capable of accepting euro or american tooling, an LED rear working light and two front sheet supports that slide with a linear rail. There is also a dual palm/foot station equipped with a selector switch. This small, powerful and precise press brake packs a punch.

Gulf States Saw & Machine. Co. carries a variety of hydraulic press brake models to suit the needs of each of our customers. Our presses come in sizes from 22 to 440 tons, and have bed lengths of 4 to 13 feet with manual or CNC controls. We can also accommodate custom orders for lengths and tons. Our press brakes come with safety devices and a safety cage at the rear that prevents the machine from being opened. This allows for simple and secure maintenance. All electrical components are made from industry-standard parts that can be found in our Memphis, TN warehouse. For more information on each model, download a pdf.

Hydraulic Press Brake Risk Assessment