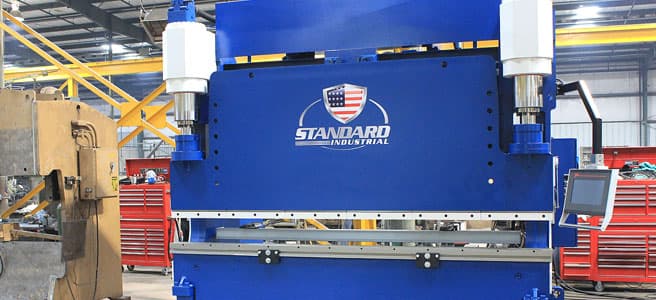

Hydraulic Press Brake Blade

Cnc Press Brake

Gulf States Saw & Machine.Co is a Member of the American Welding Society, NOMMA (National Ornamental & Miscellaneous Metals Association) and the National Glass Association:

High productivity, heavy duty bending performance, intuitive operation - all in one cost-efficient package