Hydraulic Press Brake Jack

How long should hydraulic brakes last

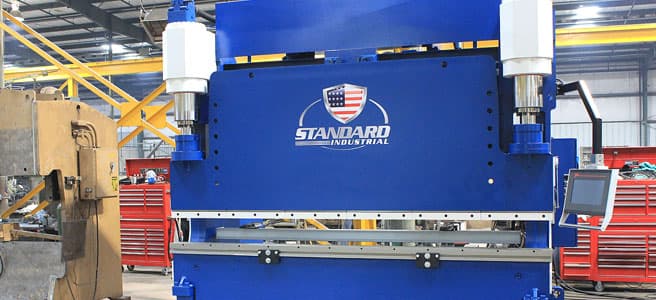

Our Servo Hydraulic Press brakes are efficient and powerful metal benders. They consume up to 66% less power during standby and use 44% less energy during the bending process. Our servo brakes are powered by AC Servo electric motors that drive hydraulic oil "on-demand" through variable speed pumps. The servo press brake has a lower cost per unit because it uses our advanced technology. This allows us to synchronize the powerful forces of electric power, hydraulics and electronics only when they are needed. There is no quieter, more efficient, or more precise press brake available.

No matter what your bending requirements, the BB series can help you. Power, precision, profit, and profit are all within reach.