Hydraulic Press Brakes Jump

Hydraulic Press Brake Machine Turkey

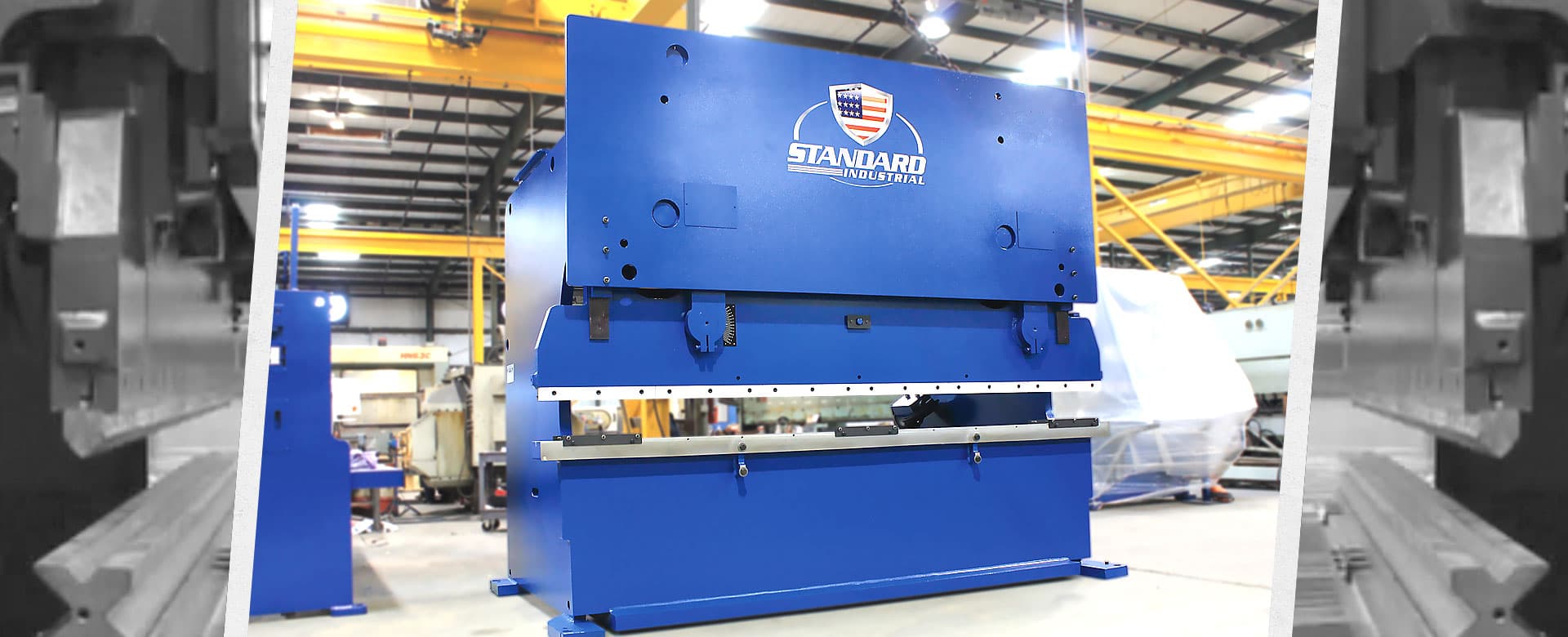

We also stock a range Press Brakes that can be used with hydraulic control systems. The hydraulic control system can bend large workpieces. It is able to work efficiently with thick metal materials due to its huge tonnage. The range can operate in Single Cylinder, Dual Cylinder Y1+Y2 format and doesn't require any complicated operations. Our Press Brakes are capable of processing steel, brass or metal sheets.

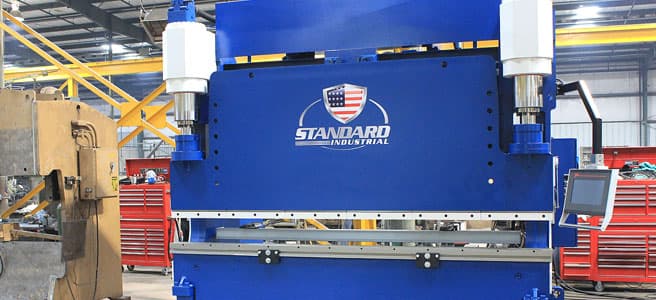

There are also the BH series "hybrid", which proves once again that not all hybrid press braking systems are created equal. These machines are the third generation and feature a dual-drive design that combines hydraulic and electric bending. They offer superior productivity, precision and reliability and energy savings.