Hydraulic Press Brake Machine Hs Code

Hydraulic Press Brake For Sale Craigslist

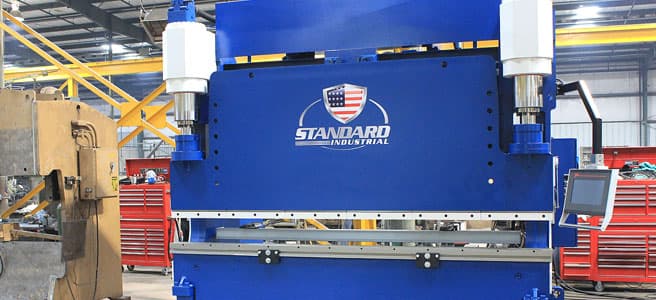

This dual drive hybrid makes quick work of any project. It's long-term, high performance, and efficient.

We provide press brakes to help improve your production, speed up production, minimize energy consumption and reduce operating cost. Our press brakes are available in sizes from 40-to-2,000-ton capacities, with anywhere from 3-11 axes. This includes tool layout, collision report editing, back gauge edit, and DiamondSoft(r).