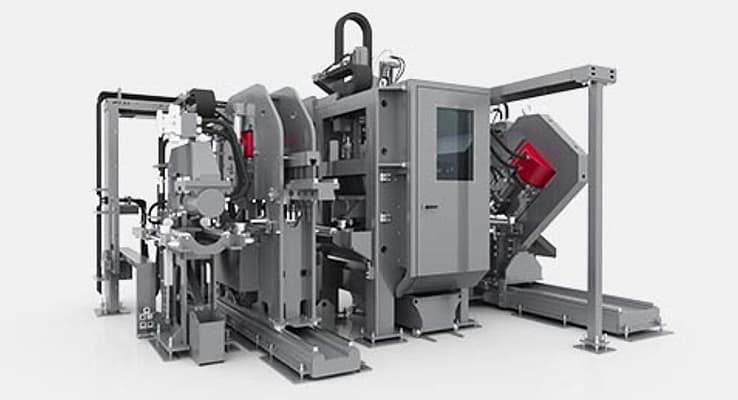

Beam Layout Welding Program

Gulf States Saw & Machine Company, a Tampa-based company, was founded in 1984 with the goal of helping clients obtain superior products in the cutting-throat metal fabrication industry. CMT's services grew to include additional showrooms in Atlanta and Dallas, TX. Capital is now present in 12 states: Florida, South Carolina and Virginia, Mississippi. Tennessee, Texas. Georgia. North Carolina. Alabama. Louisiana. Oklahoma.

.jpg)