Beam Layout Welding Disadvantages

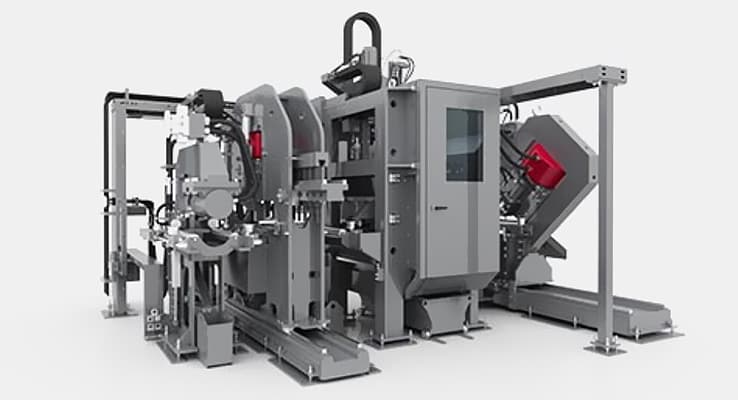

H Beam layout is more than just one machine. It is comprised of many parts with different functions and features. Beam layout suppliers and manufacturers can use a wide range of materials to make their beams. Most H beam welding equipment are made from different types and grades of steel.