Beam Layout Welding Is A Joining Process

H Beam layout welding equipment is more than a one-off piece. It is composed of many different parts with different functionalities and features. Beam layout machine manufacturers and suppliers use many different materials to produce their H beams. H beam welding machine are made mostly from different types of metal.

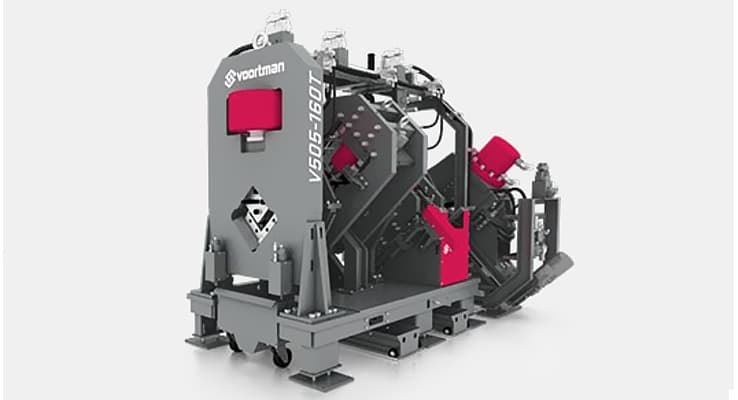

.jpg)