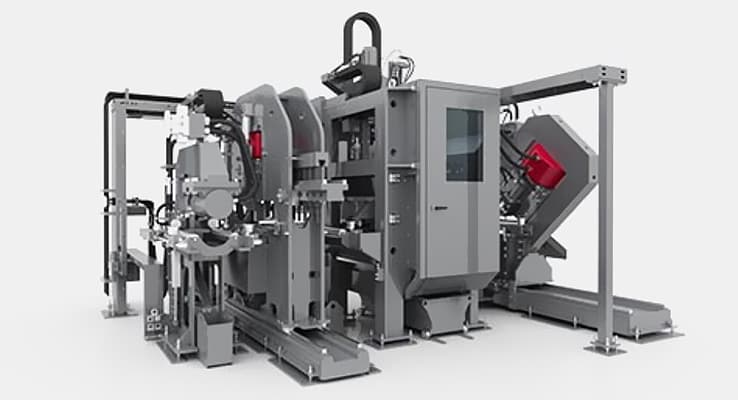

Oscillating

With the help of our Research & Development team, we can create the exact Beam Layout welding machine that you require. If you think it is possible, let us know and we will get back to your with our findings! Our engineers are more than happy to assist you! Get a quote for the equipment or products that you are looking for by contacting us today!