Production

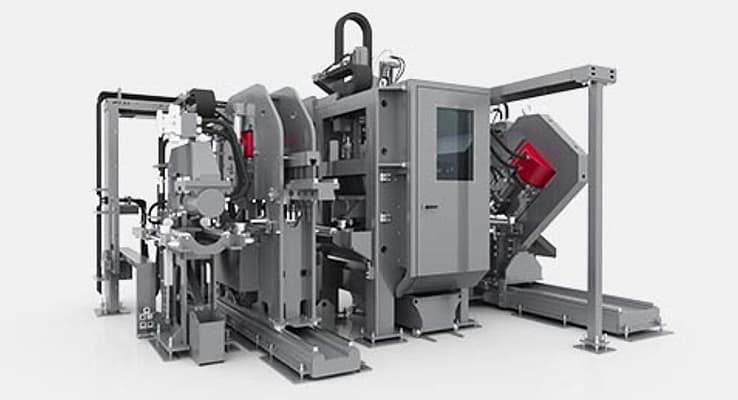

Gulf States Saw & Machine Co., Inc. has the largest saw blade shop in southeast. We have more than 50,000 products for our customers through our supply list. We are as committed to our clients' satisfaction as we are to making huge sales.