Small Scale.That

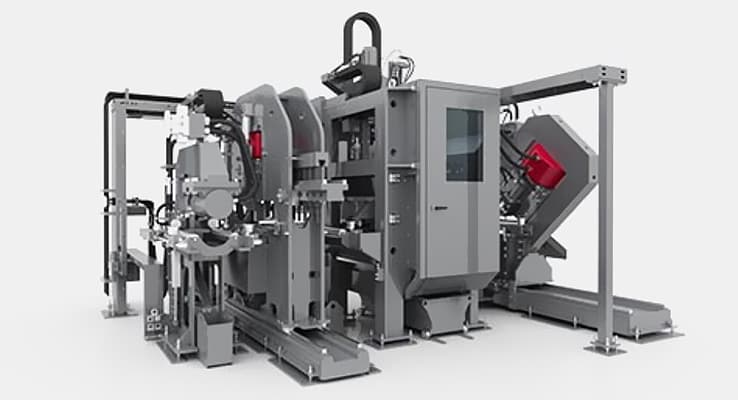

Beam layout welding doesn't only involve manual welding; an H beam fabrication machine or line can actually work on multiple H-beams simultaneously. It is a flat-laid machine that feeds long uncut plates. It also handles the welding of each individual plate to create the design requested by the client.