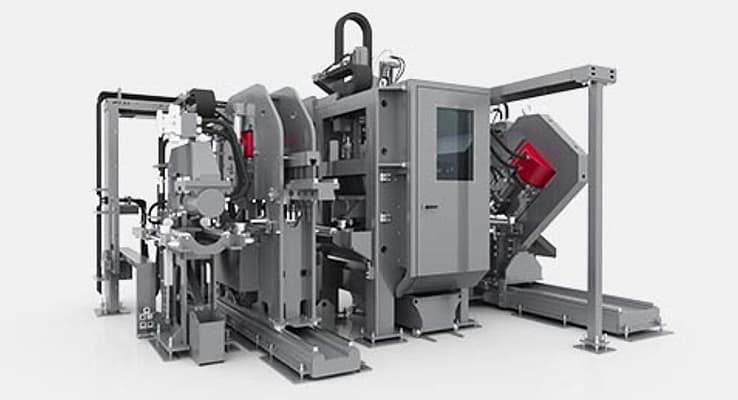

Beam Layout Welder Job Description

The platform comes with rail guards and steps for easy access. This platform can be used to store flux and wire. It also allows the operator to load fluxhoppers, change reels, and make other adjustments. Add auxiliary equipment such as the PHI Flange Tilting Device or Beam Turning Device to improve your beam layout welding's speed, efficiency, and productivity.